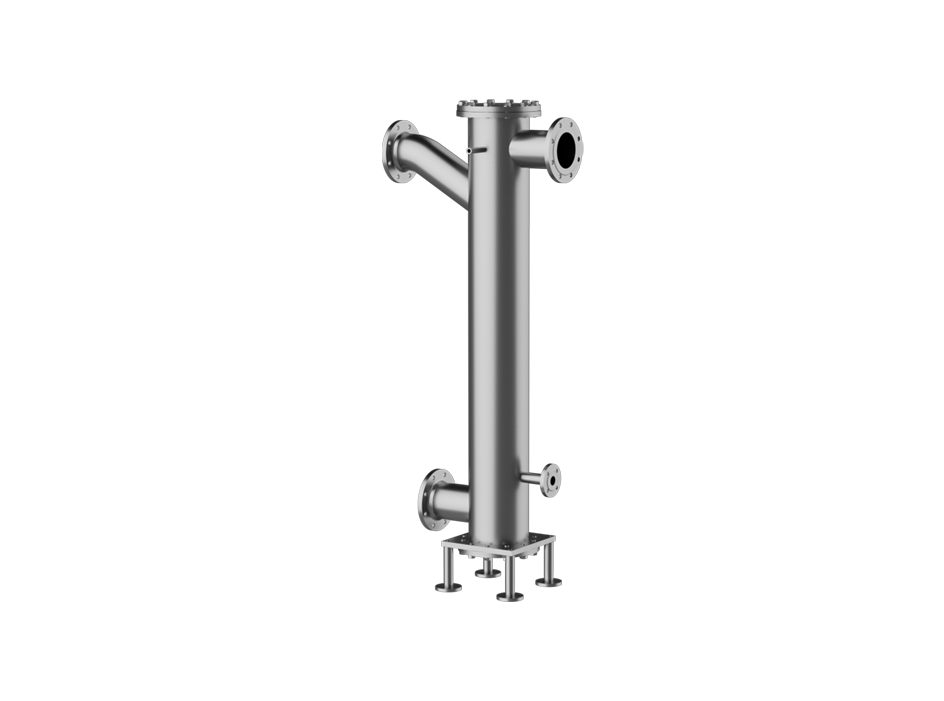

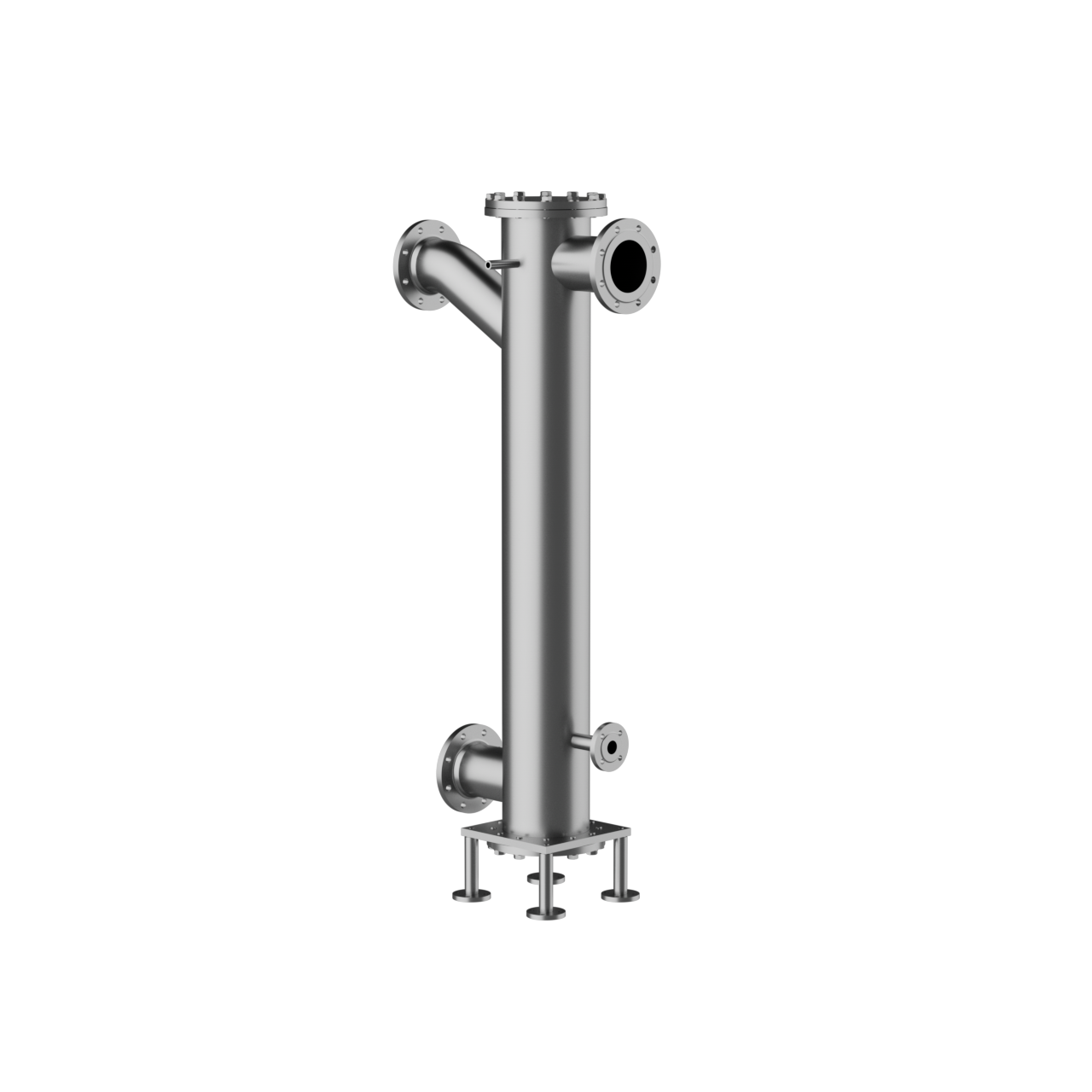

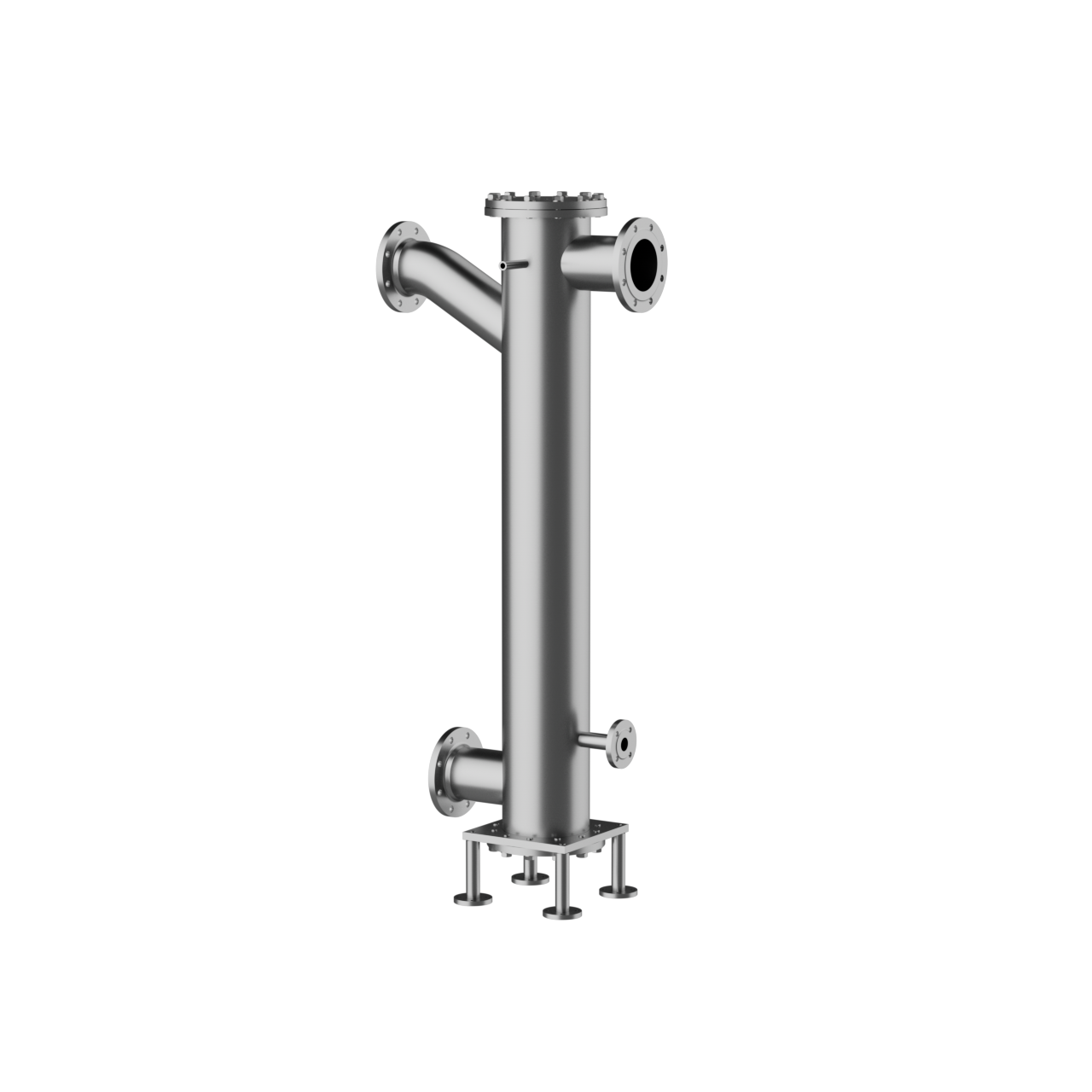

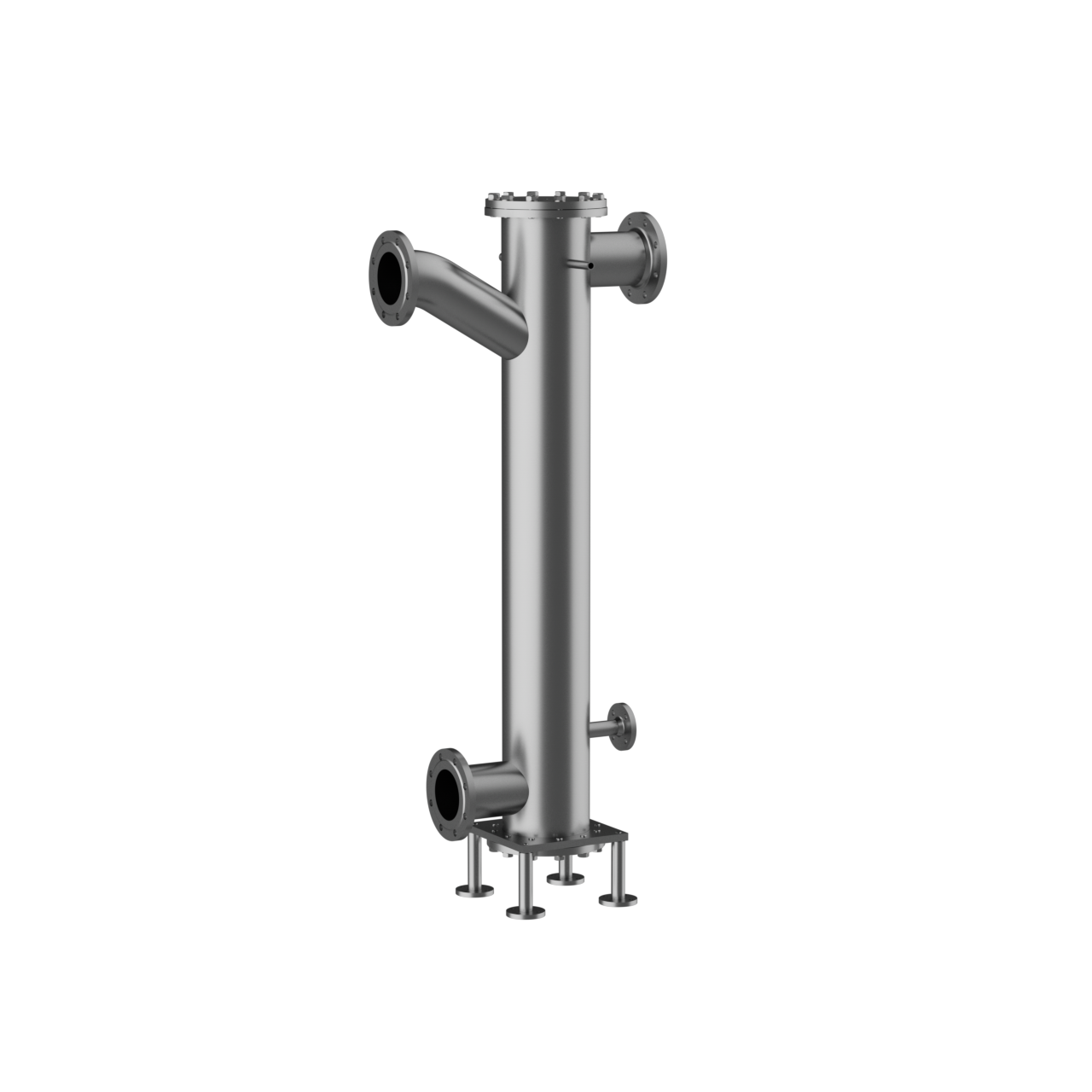

Heating Condensers

Customized and efficient condensers for your system

Condensers (liquefiers) play a crucial role wherever gaseous media need to be converted into a liquid state. They can be used, for example, in refrigeration systems or heat engines to liquefy exhaust steam or gaseous refrigerants, enabling a closed-loop process in combination with a steam generator (evaporator).

Definition and Function of Heating Condensers

Condensers (liquefiers) are special heat exchangers in which a vaporous (gaseous) substance, called vapor, is liquefied (condensed) by cooling. Thus, condensers convert gaseous media into a liquid state. In surface condensers, the condensation of vapor occurs on the surface of a heat exchange wall. The vapor and the resulting condensate on one side, as well as the coolant on the other, flow in separate spaces. Heat exchange occurs indirectly through the condenser separating wall.

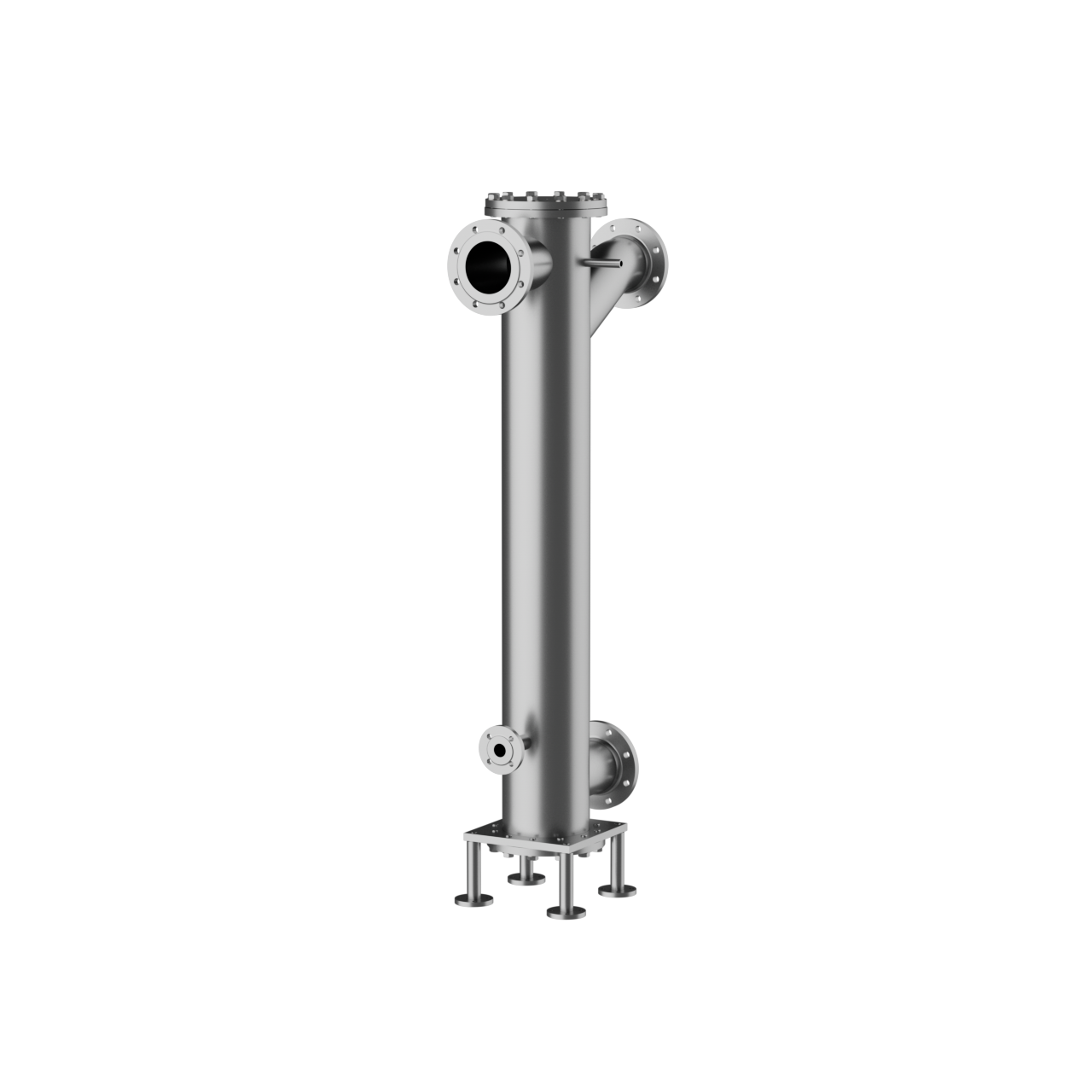

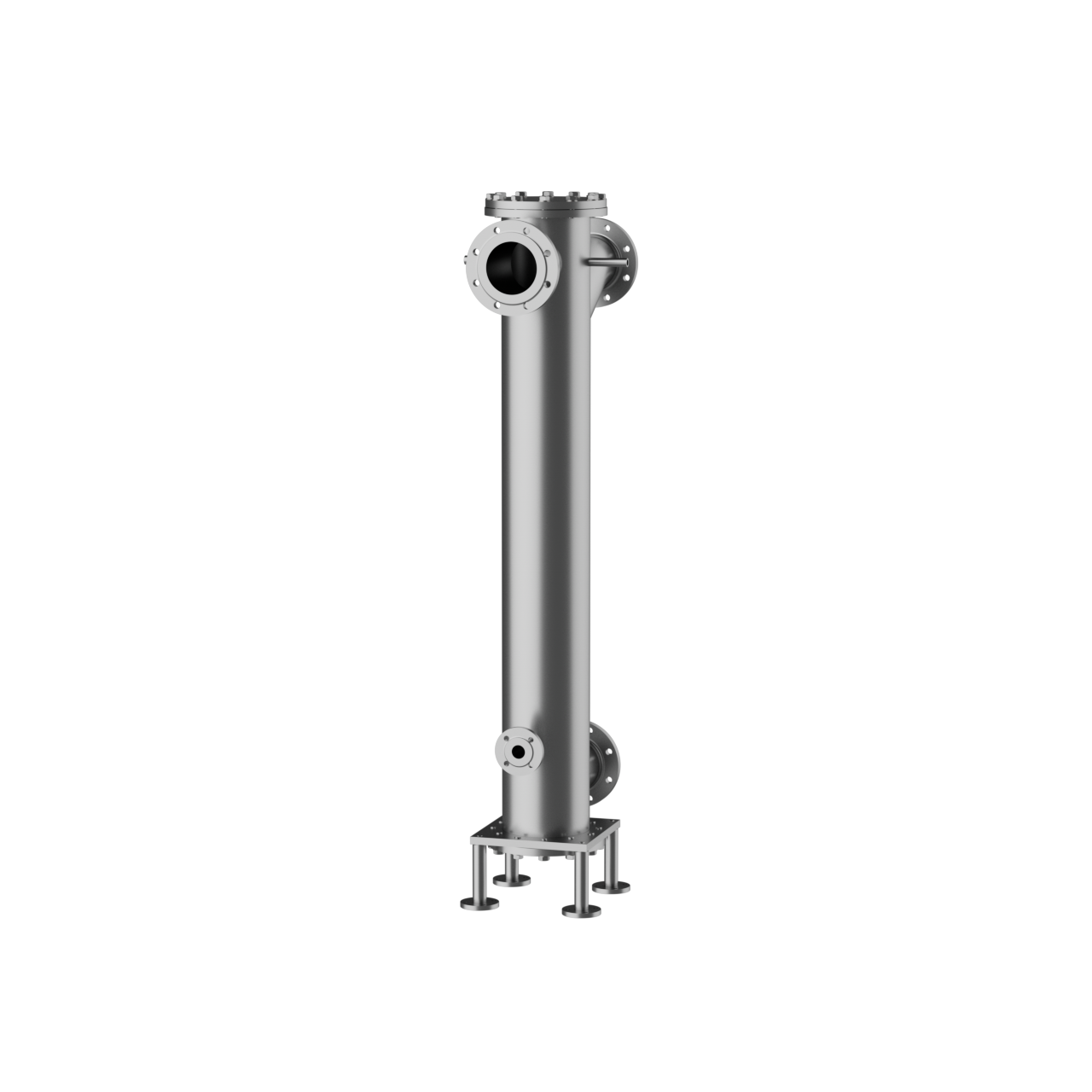

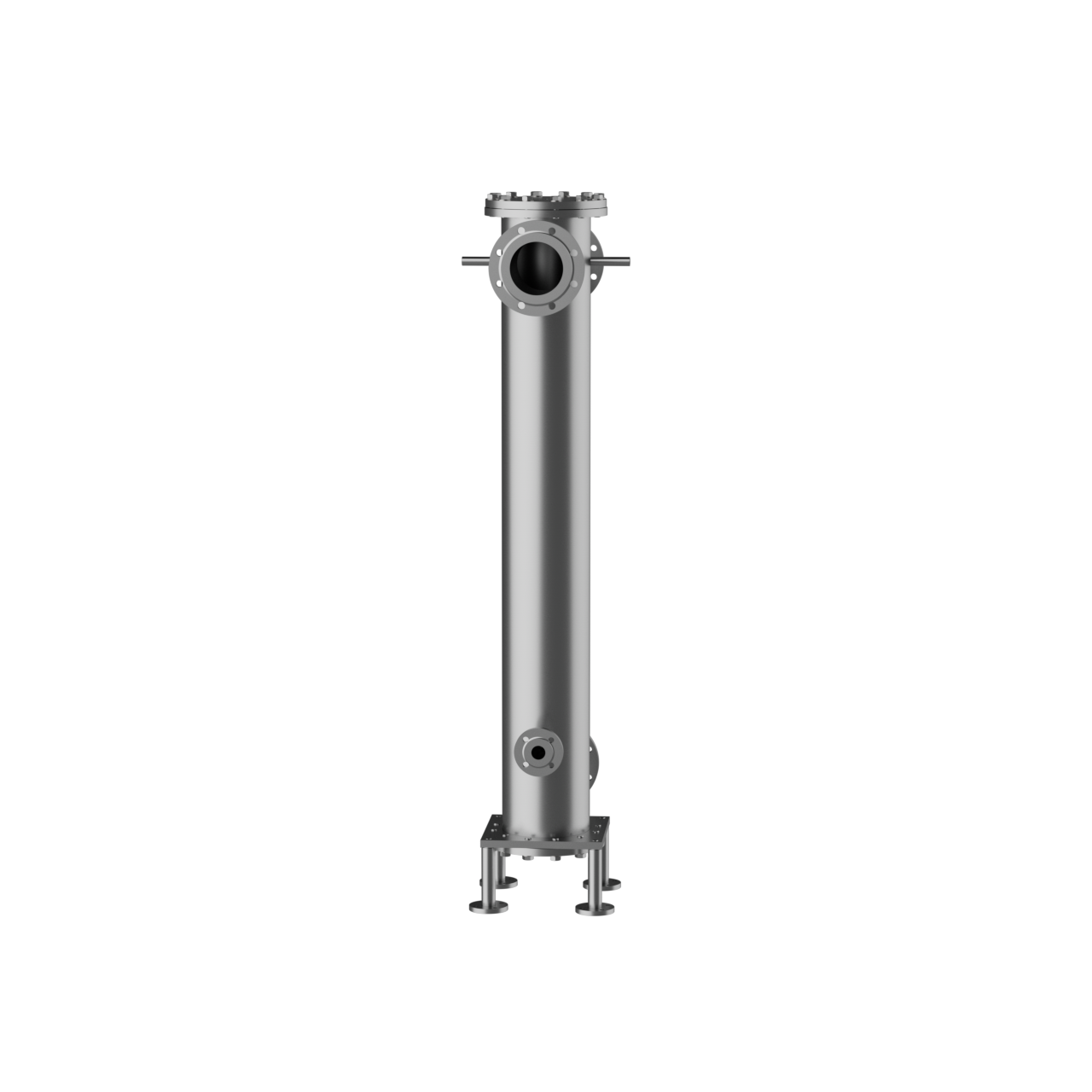

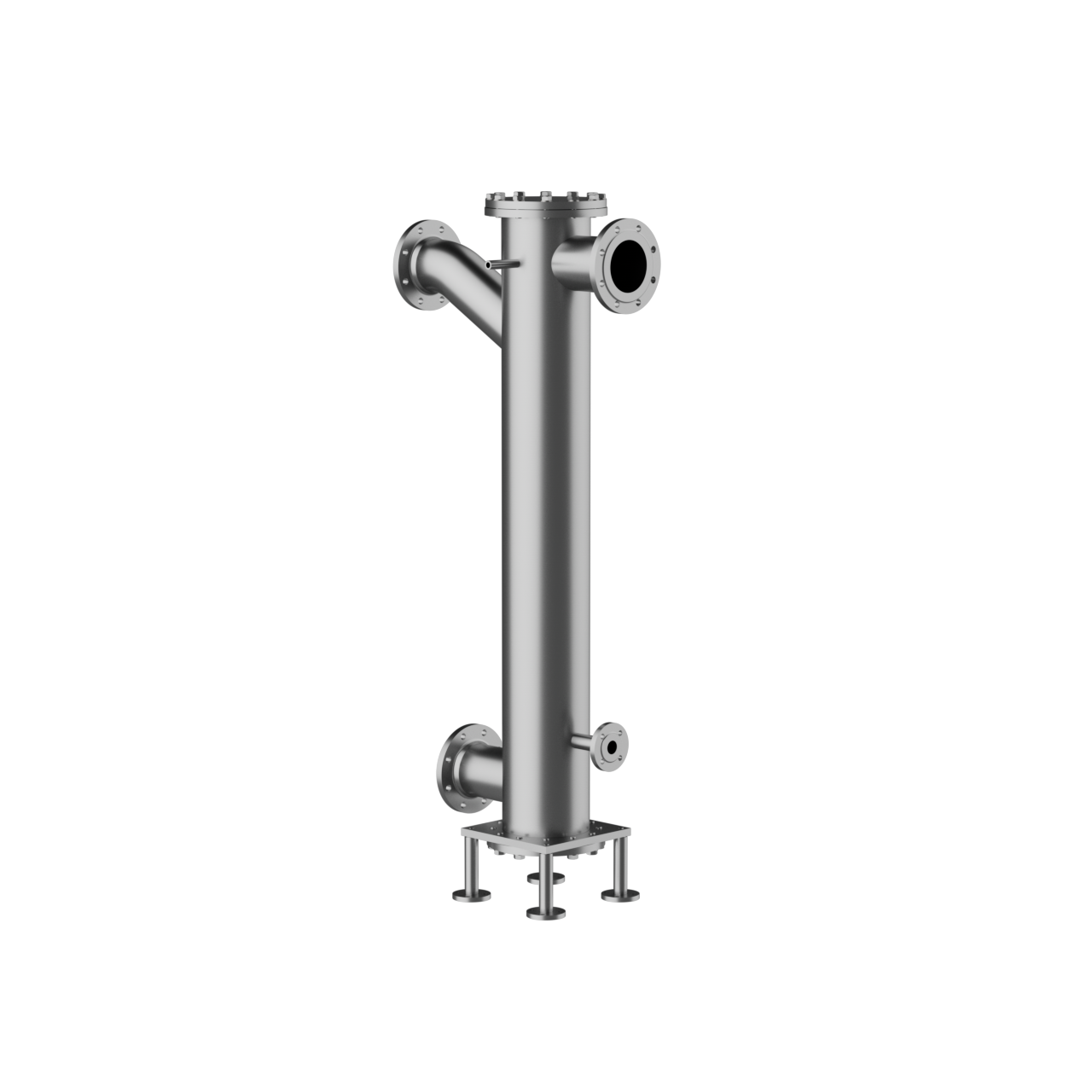

The most commonly used surface condensers are shell and tube condensers. Shell and tube condensers are usually installed horizontally with a slight incline. The coolant flows in at the low end and exits heated at the elevated connection. The vapor flows around the tubes in the shell space and condenses on the outer tube surfaces. Baffle plates cause vapor turbulence and thus better heat transfer. The formed condensate drips down the tubes and collects at the lowest point, where it is discharged via a condensate drain.

Applications

Condensers are used when the condensate contains, for example, toxic substances or solvents that must not mix with the coolant. They can also be used, for example, in refrigeration systems or heat engines to liquefy exhaust steam or gaseous refrigerants, enabling a closed-loop process in combination with a steam generator (evaporator). Furthermore, condensers (liquefiers) are used in rectification columns as cooling at the column head to initiate condensation (liquefaction).

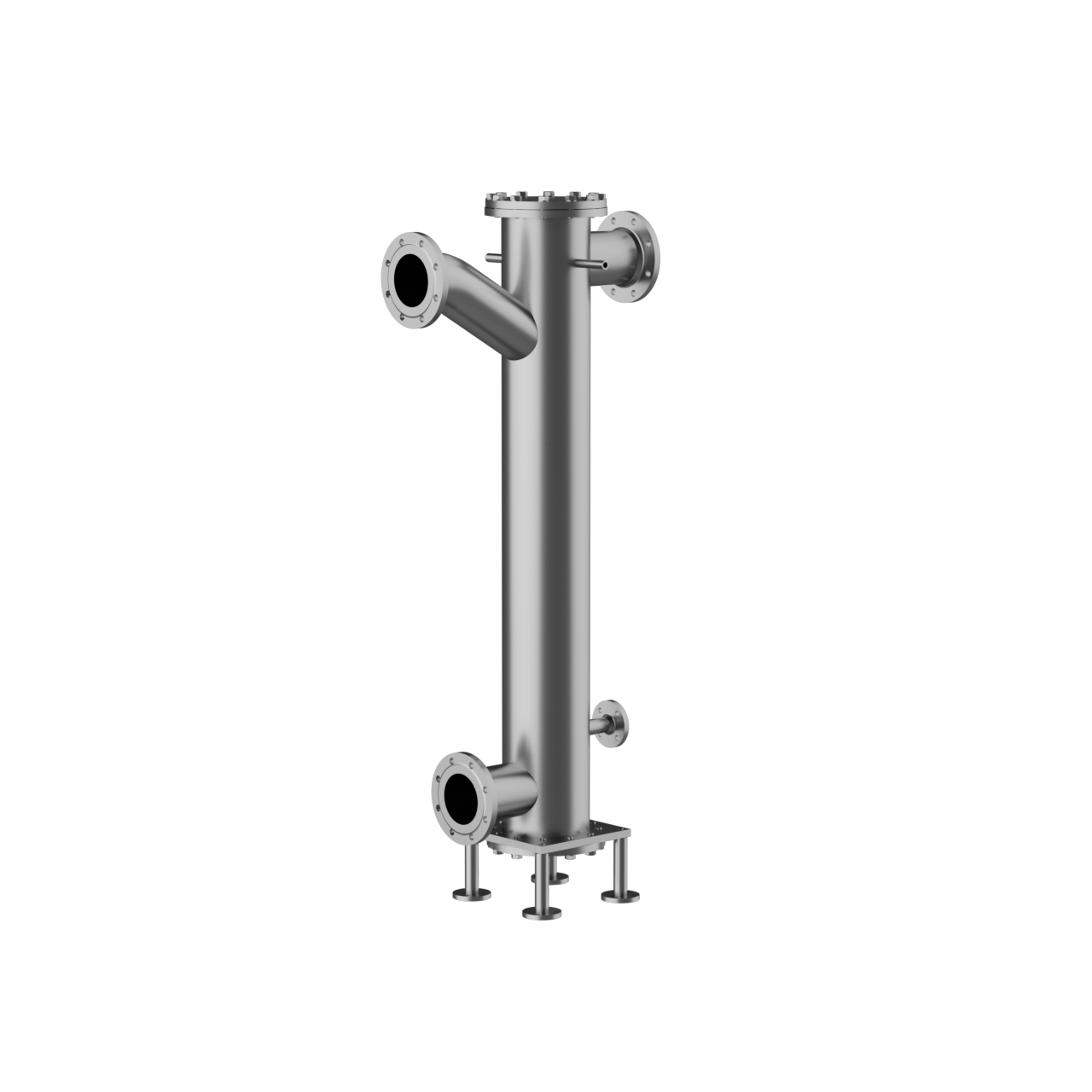

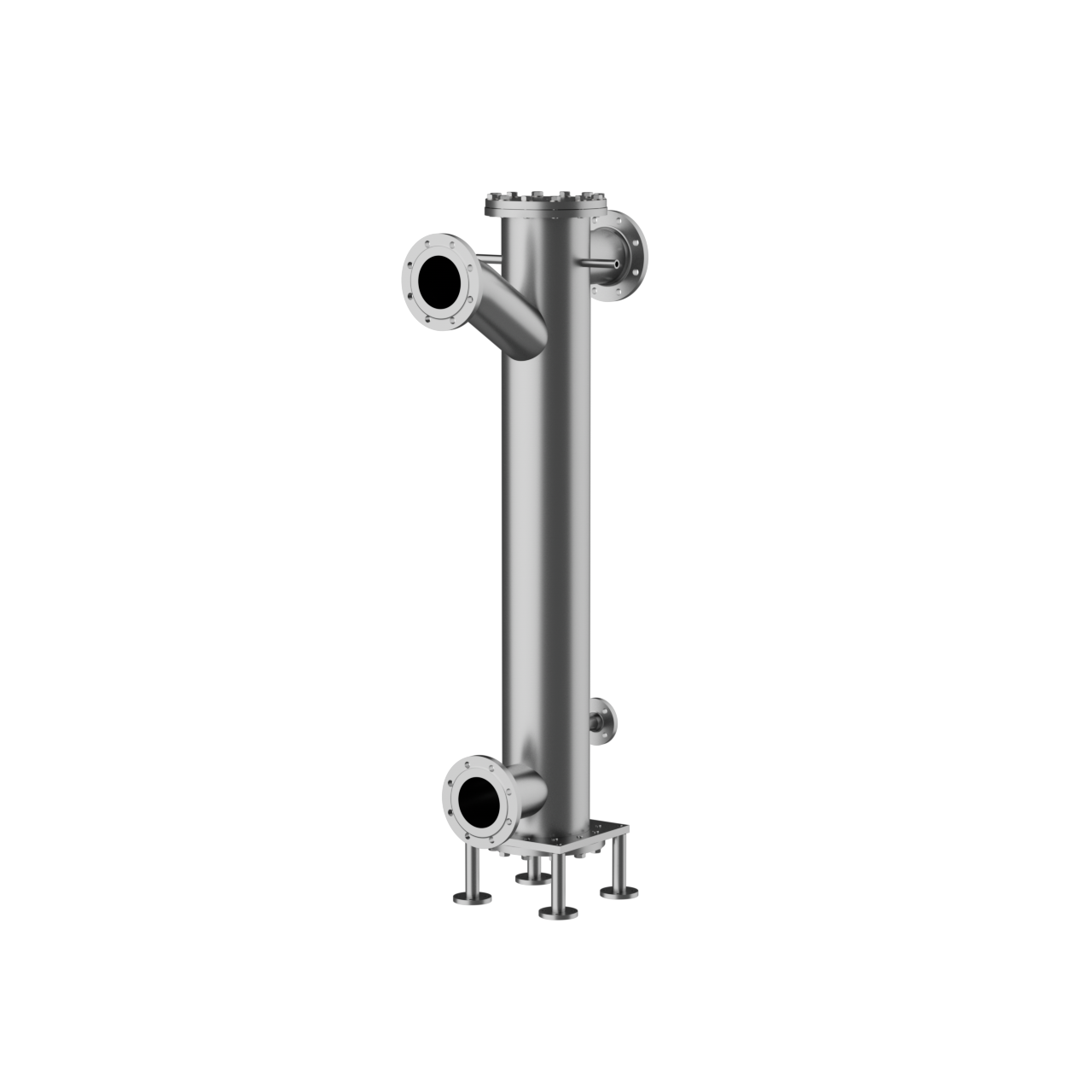

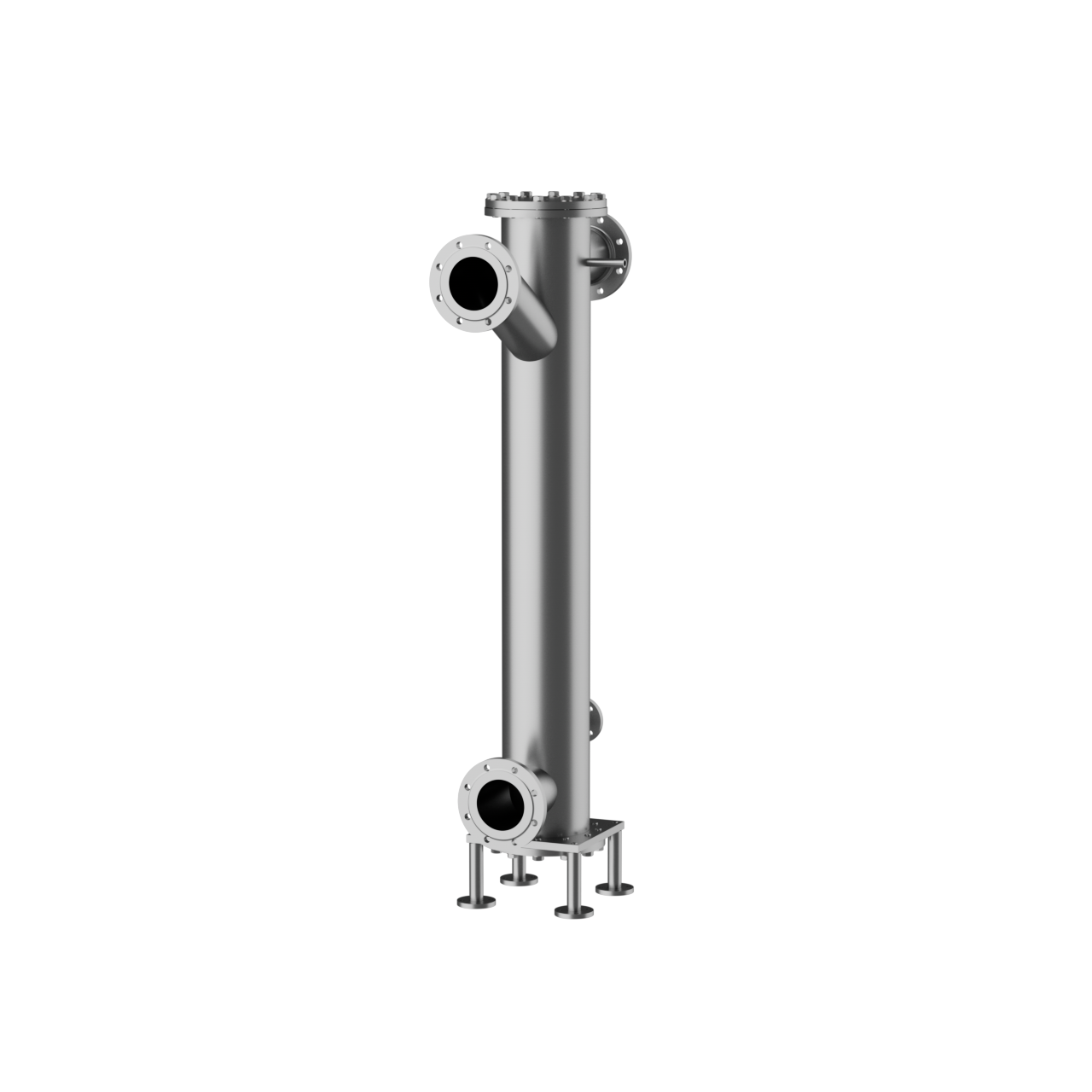

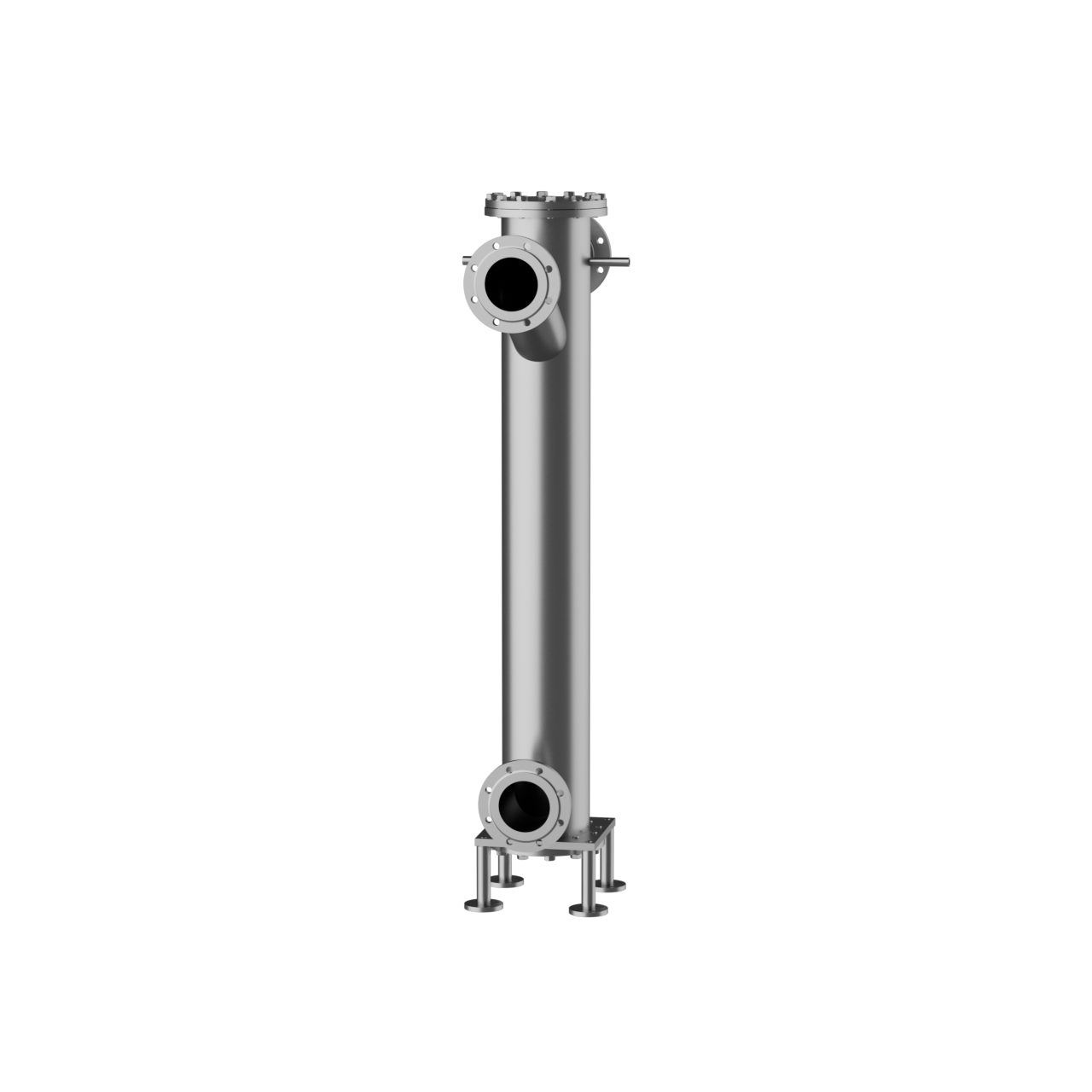

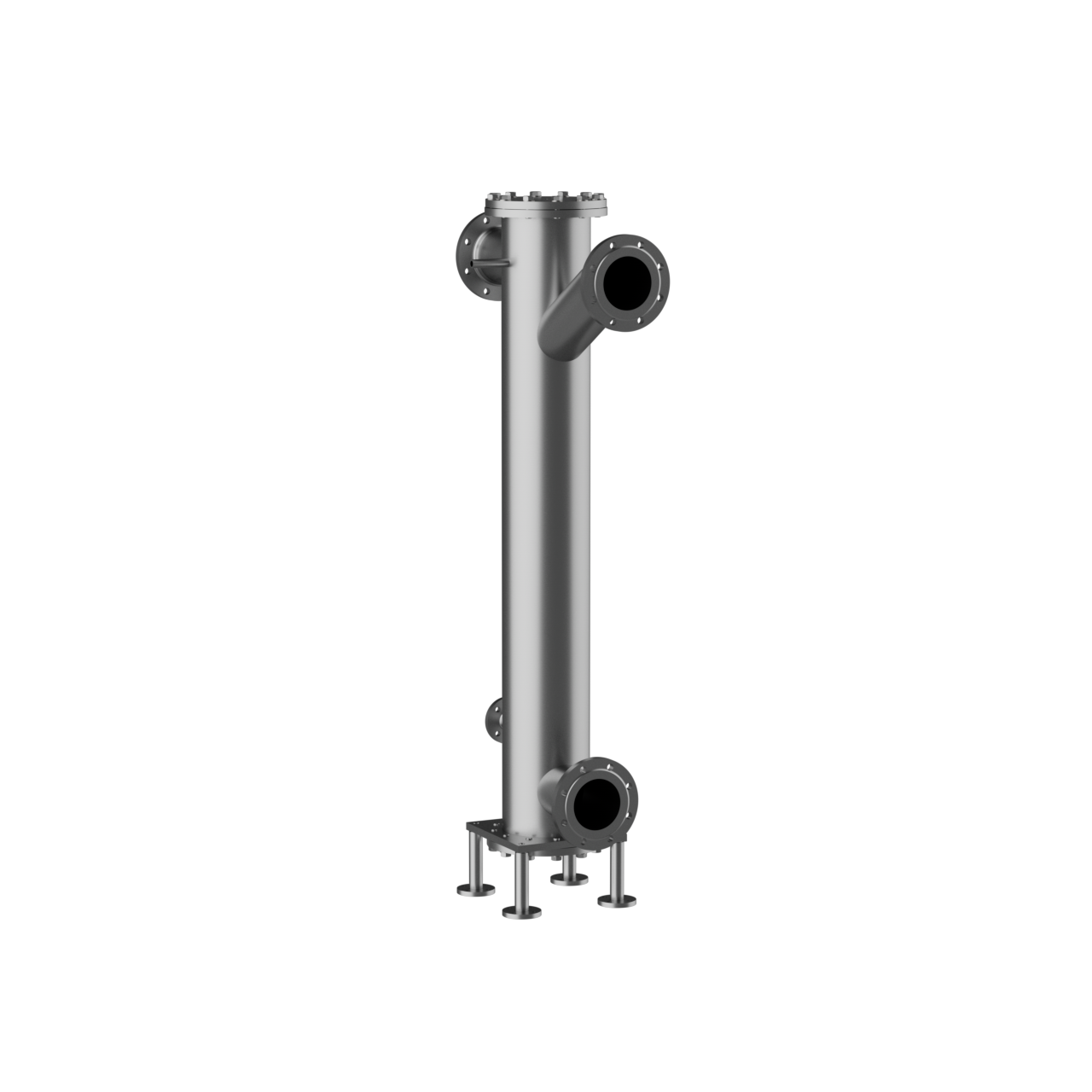

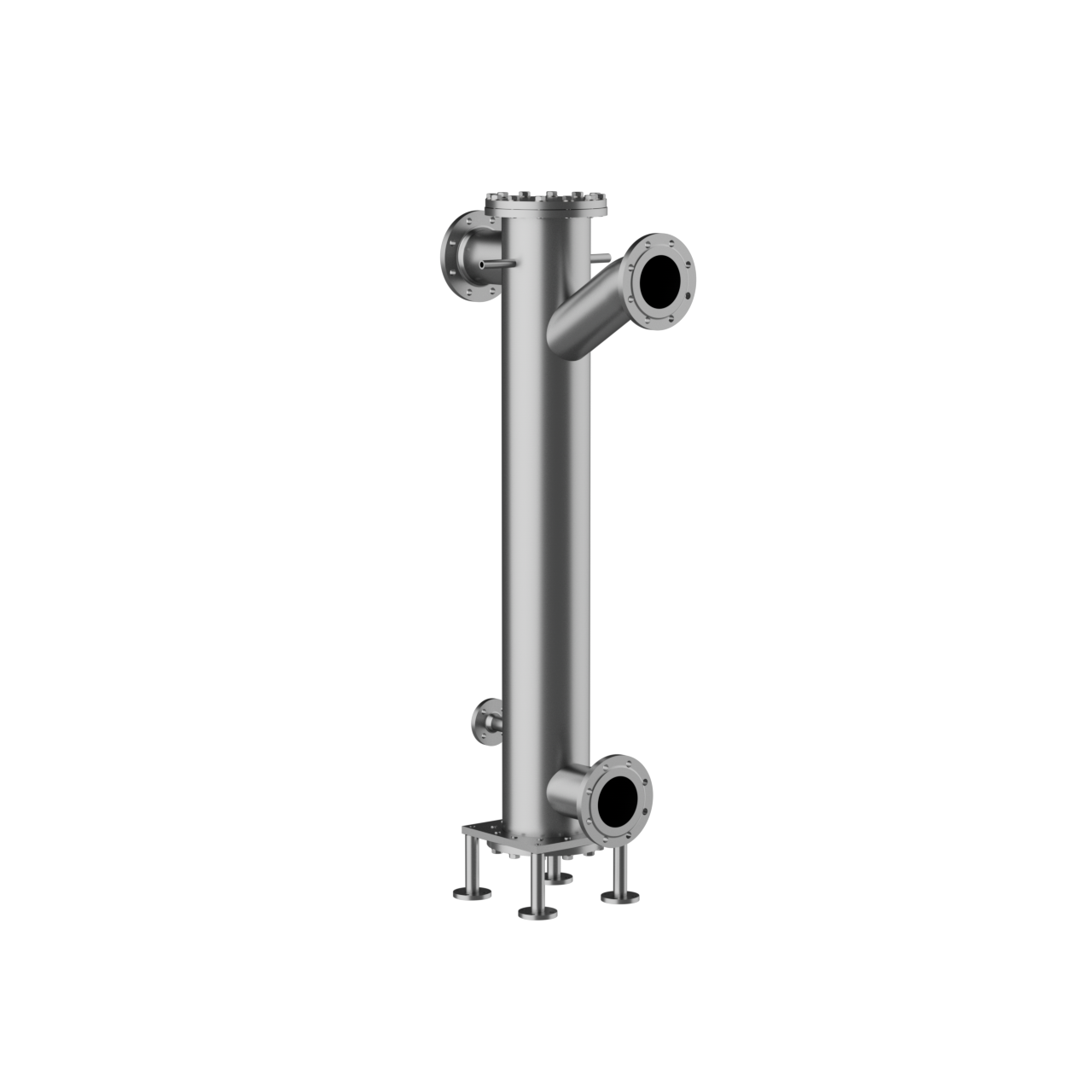

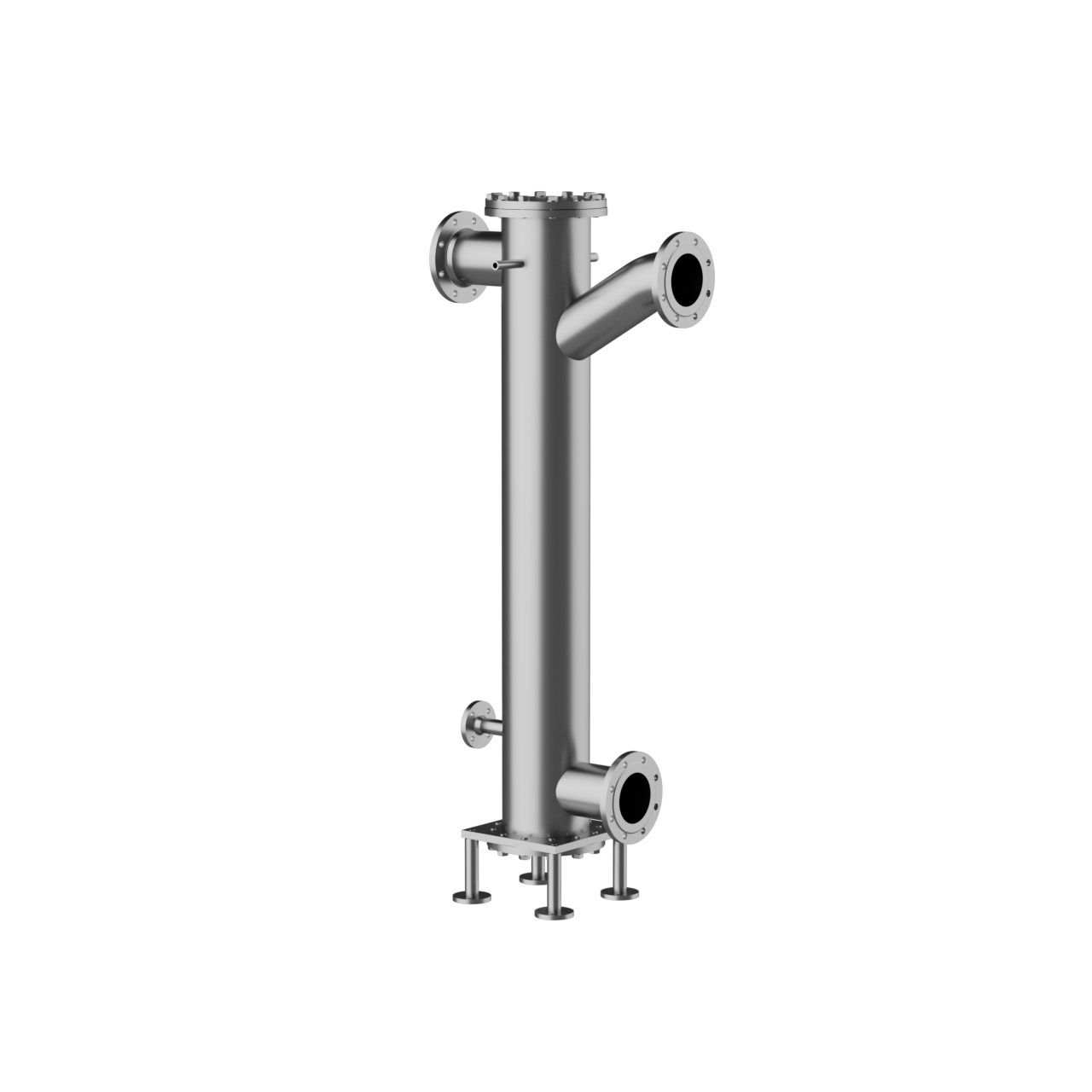

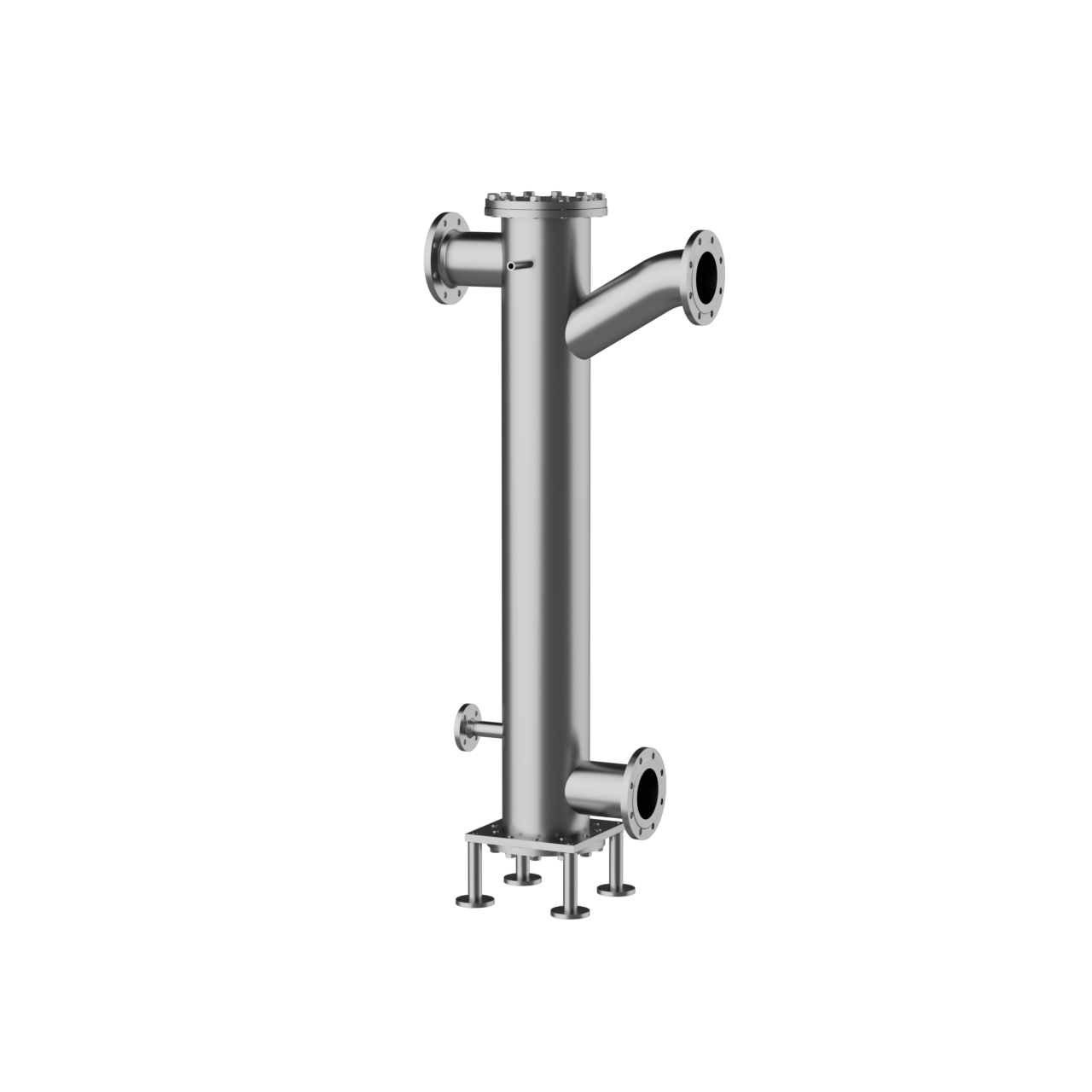

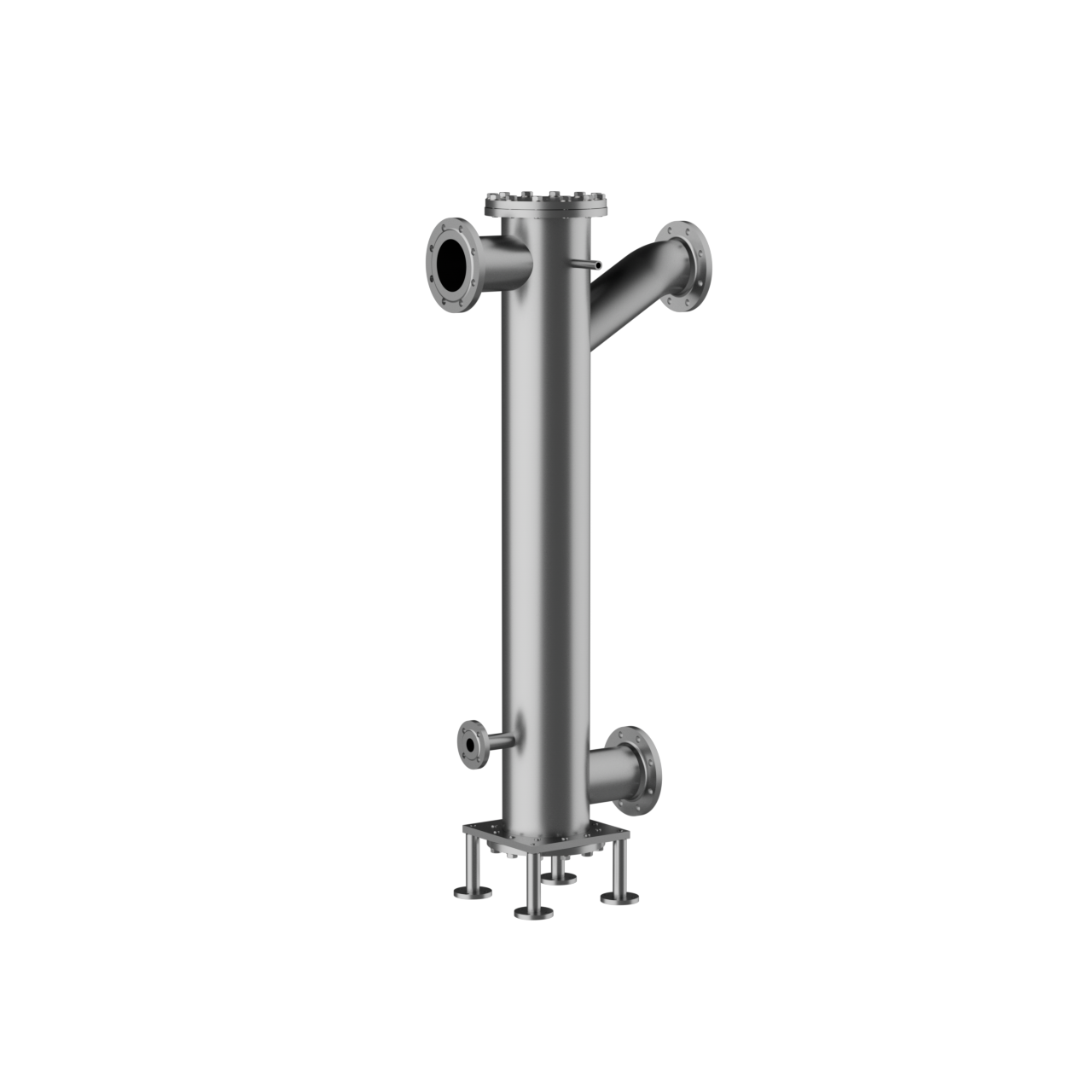

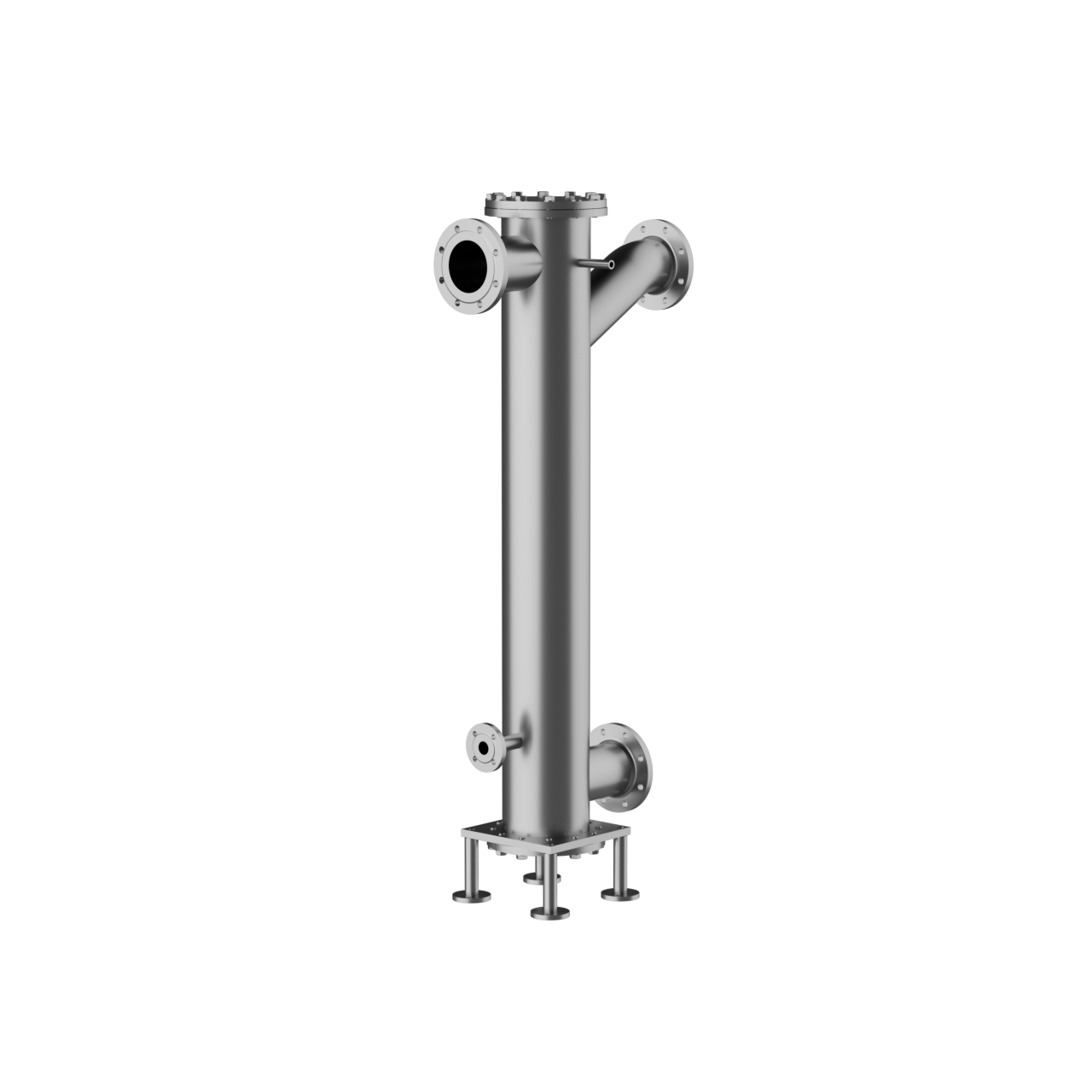

With the special heat exchangers from ZILONIS Energy Solutions with U-tube and straight-tube designs, you can implement a condenser (liquefier) in your system.

Materials and Quality

The heat exchangers calculated, designed, and manufactured by ZILONIS Energy Solutions for condensation (liquefaction) are available in various materials depending on requirements. Particularly durable and less susceptible to corrosion and deposits are stainless steel versions - these are generally suitable for condensation (liquefaction) of pure steam.

For an optimal solution, we calculate each condenser individually. All on-site conditions (e.g., connections) and customer requirements are included in the design. Through decades of experience in various industries and sectors in heat exchanger construction, we have the necessary know-how to optimally calculate and manufacture condensers for every application.

Rely on ZILONIS Energy Solutions for customized condensers that optimally support your system and operate reliably in the long term.

ANWENDUNGSSPEZIFISCH

Ihre Märkte sind unsere Märkte. Jährlich verlassen über tausend Produkte ZILONIS, die weltweit eingesetzt werden, um die anspruchsvollsten Herausforderungen zu meistern.

/chemie-und-petrochemie.jpg)

/energietechnik.jpeg)

/pharmaindustrie.jpg)

/gebaeudetechnik.jpeg)

/holz-und-papierindustrie.jpeg)