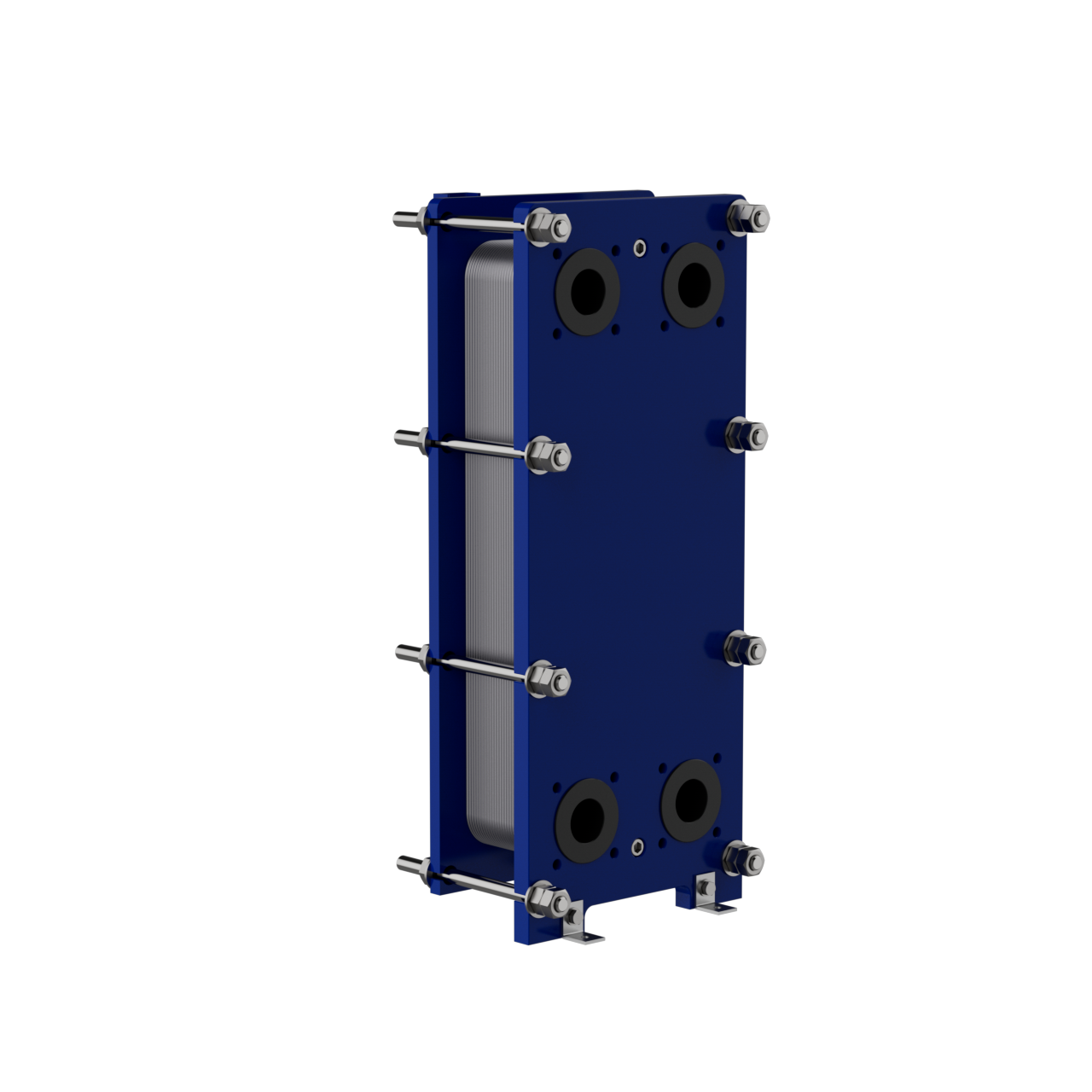

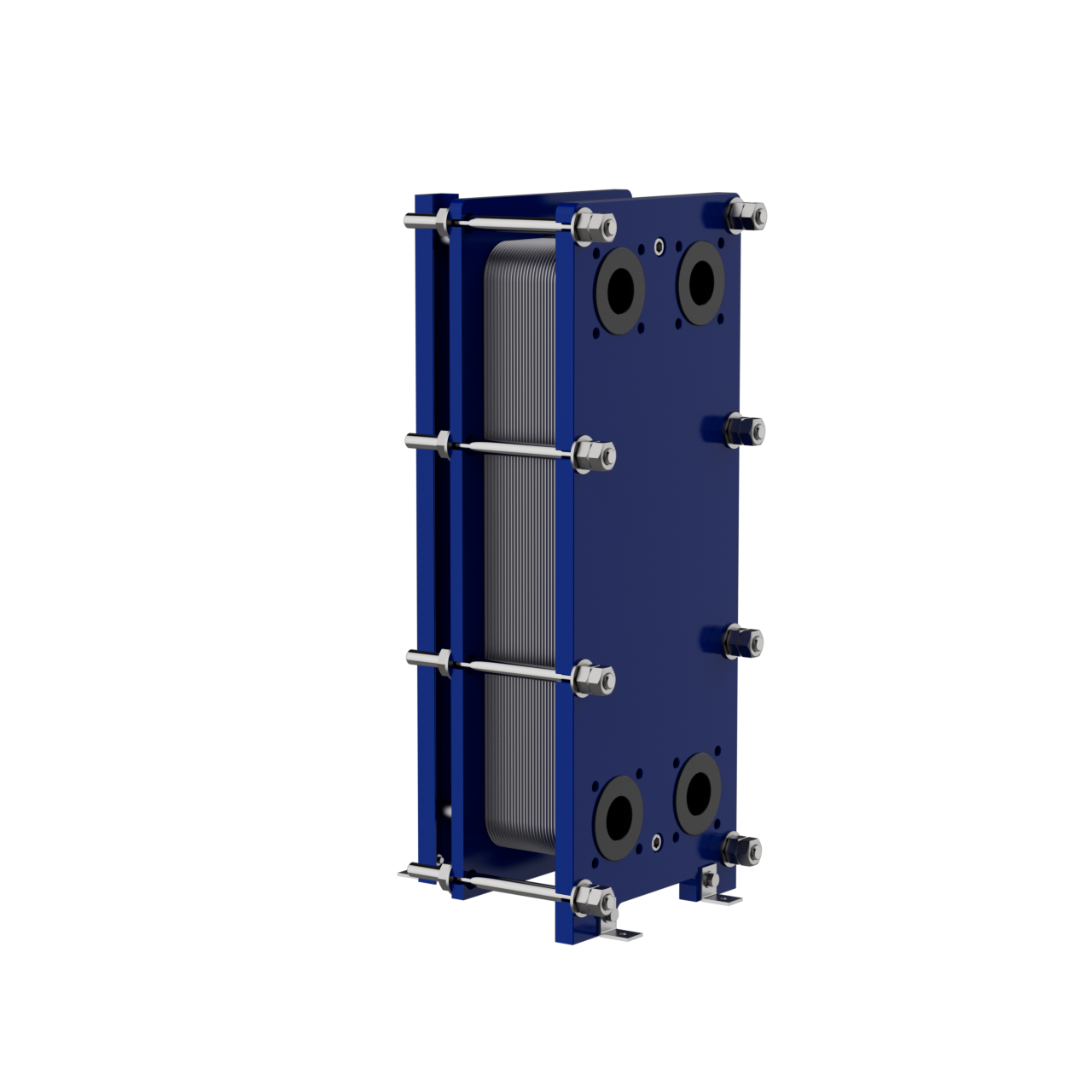

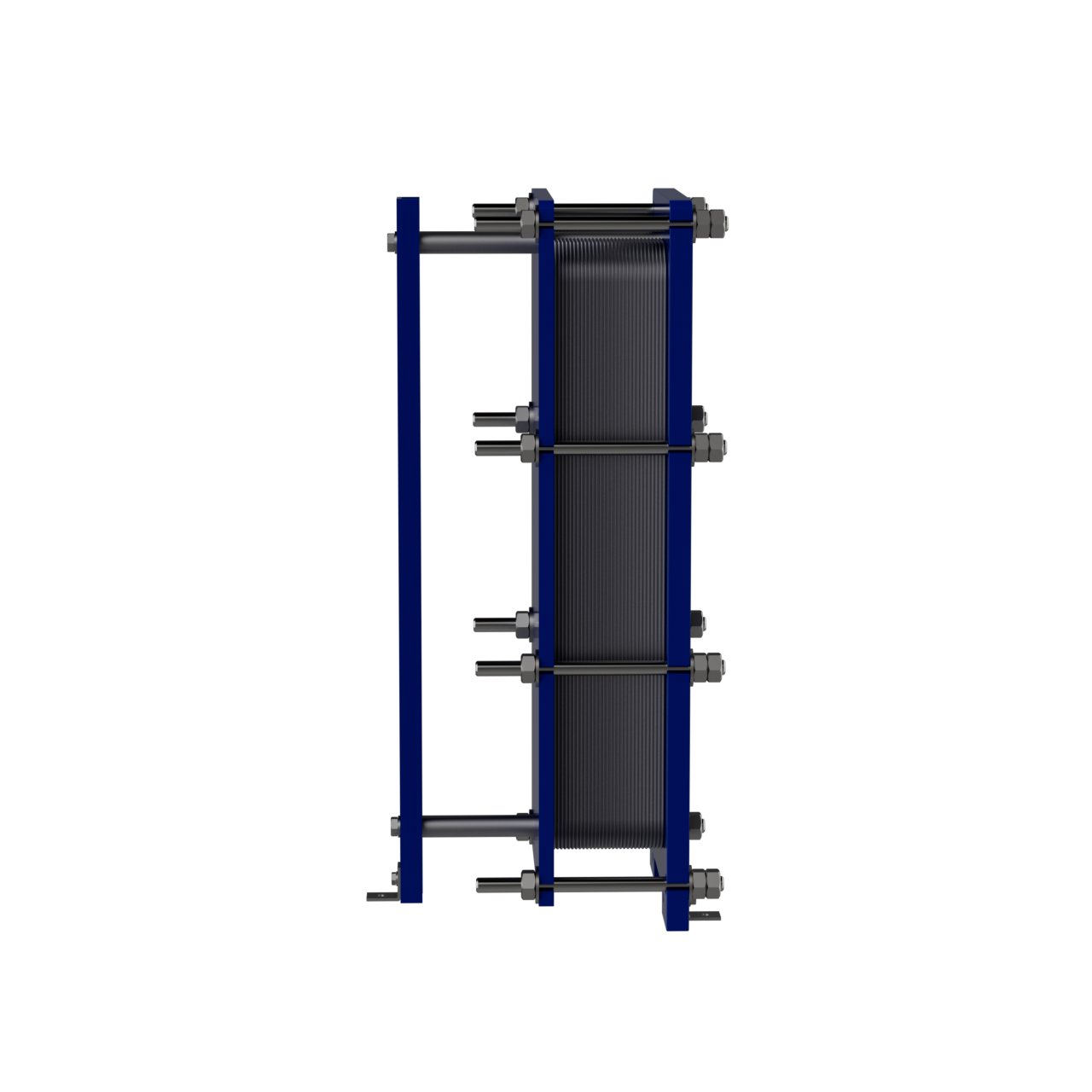

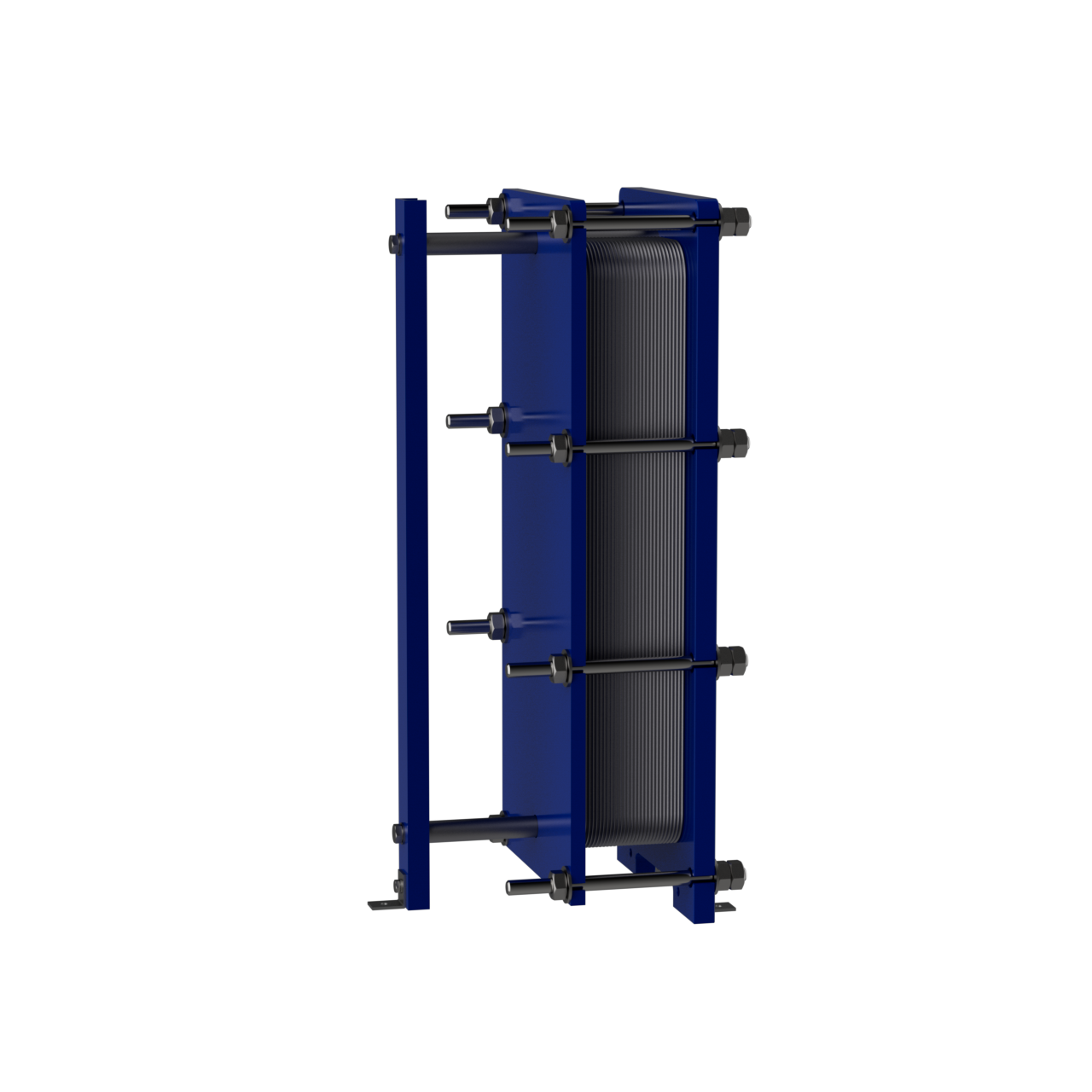

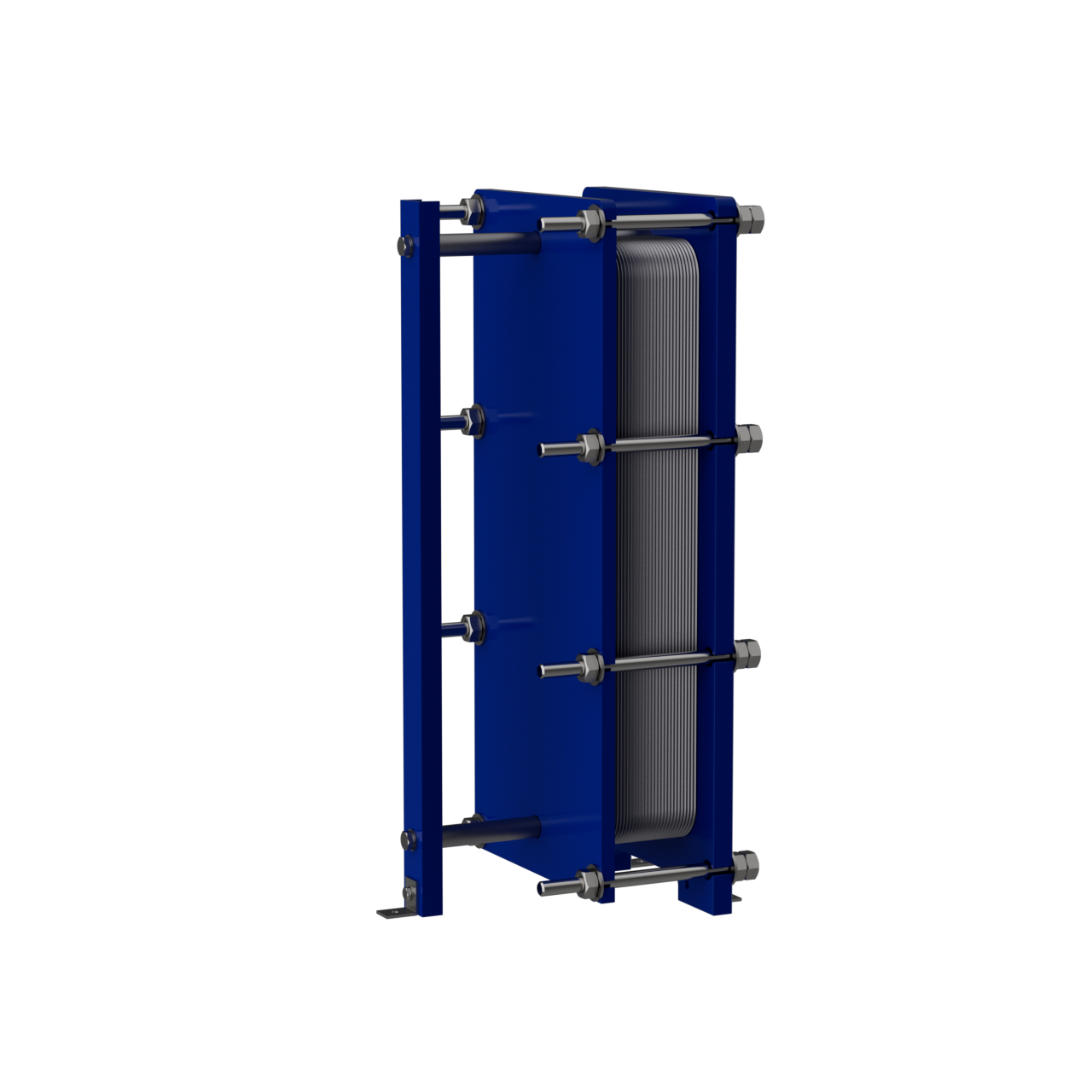

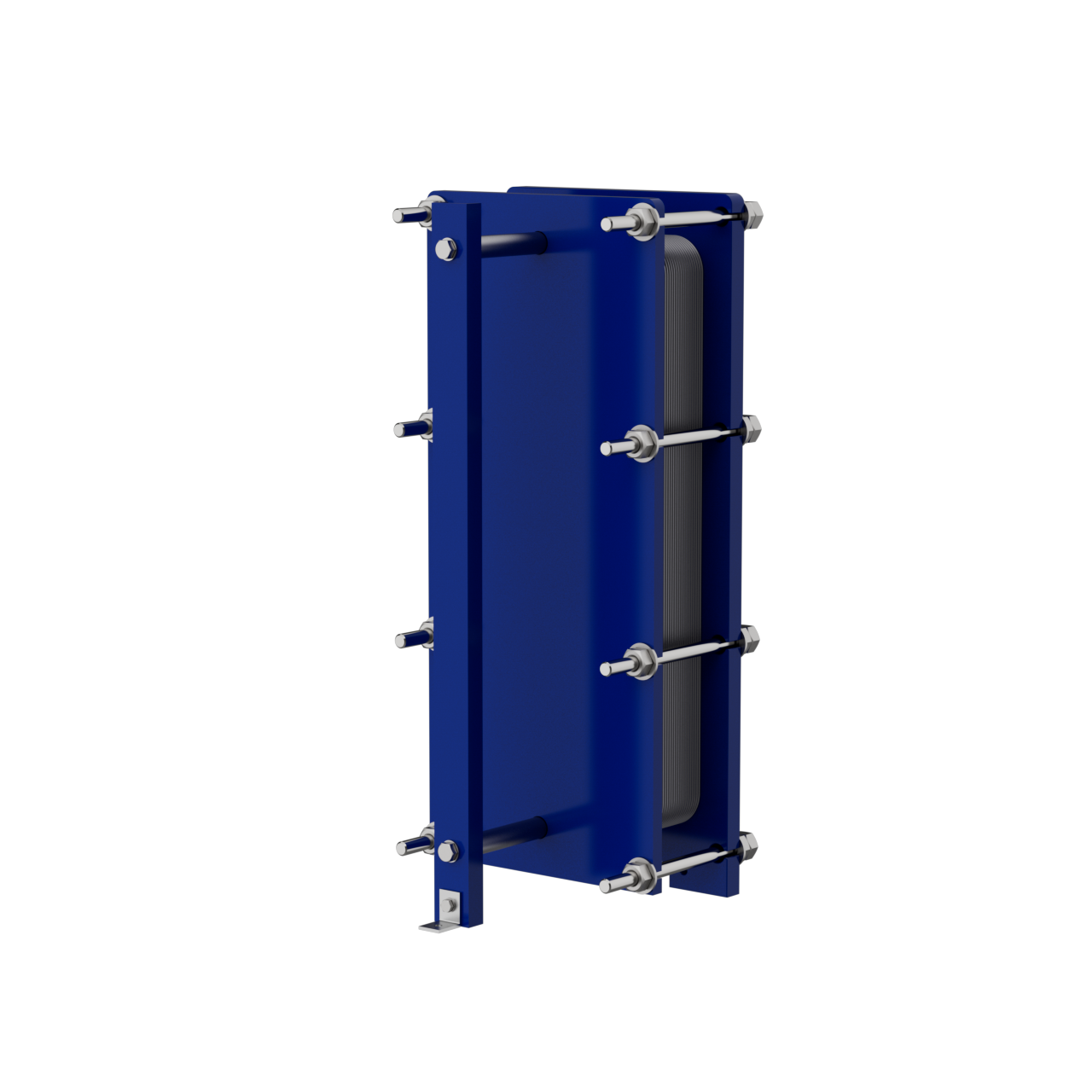

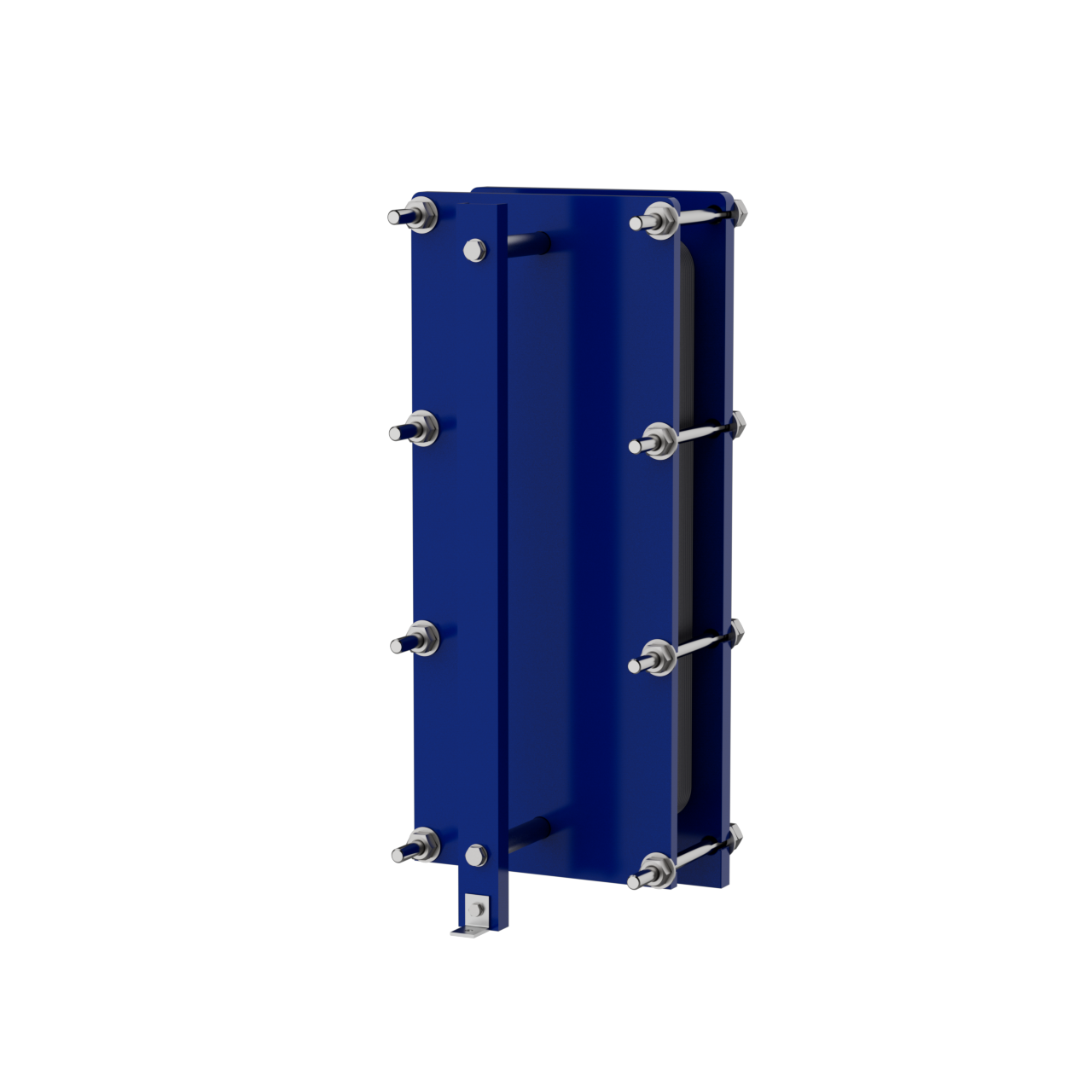

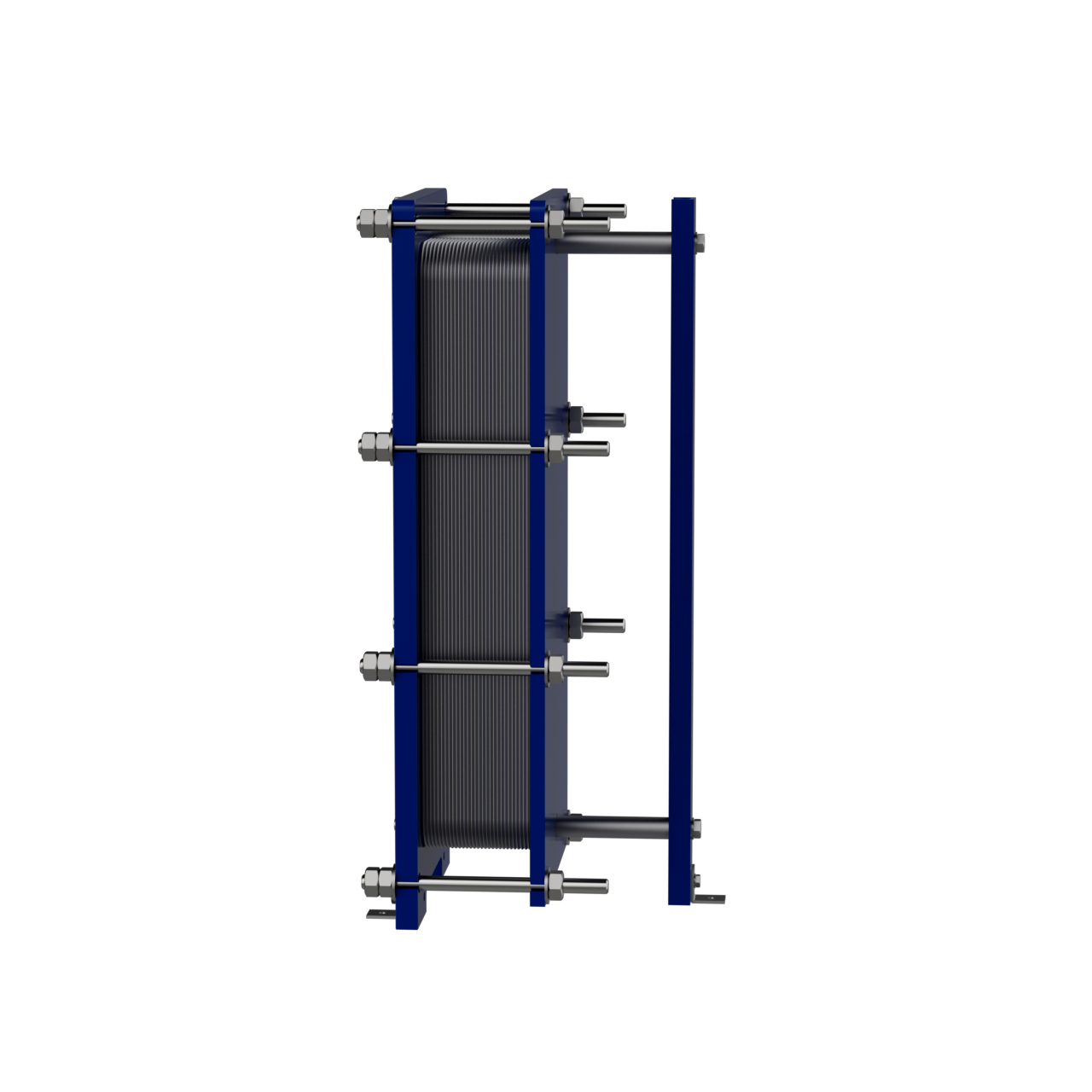

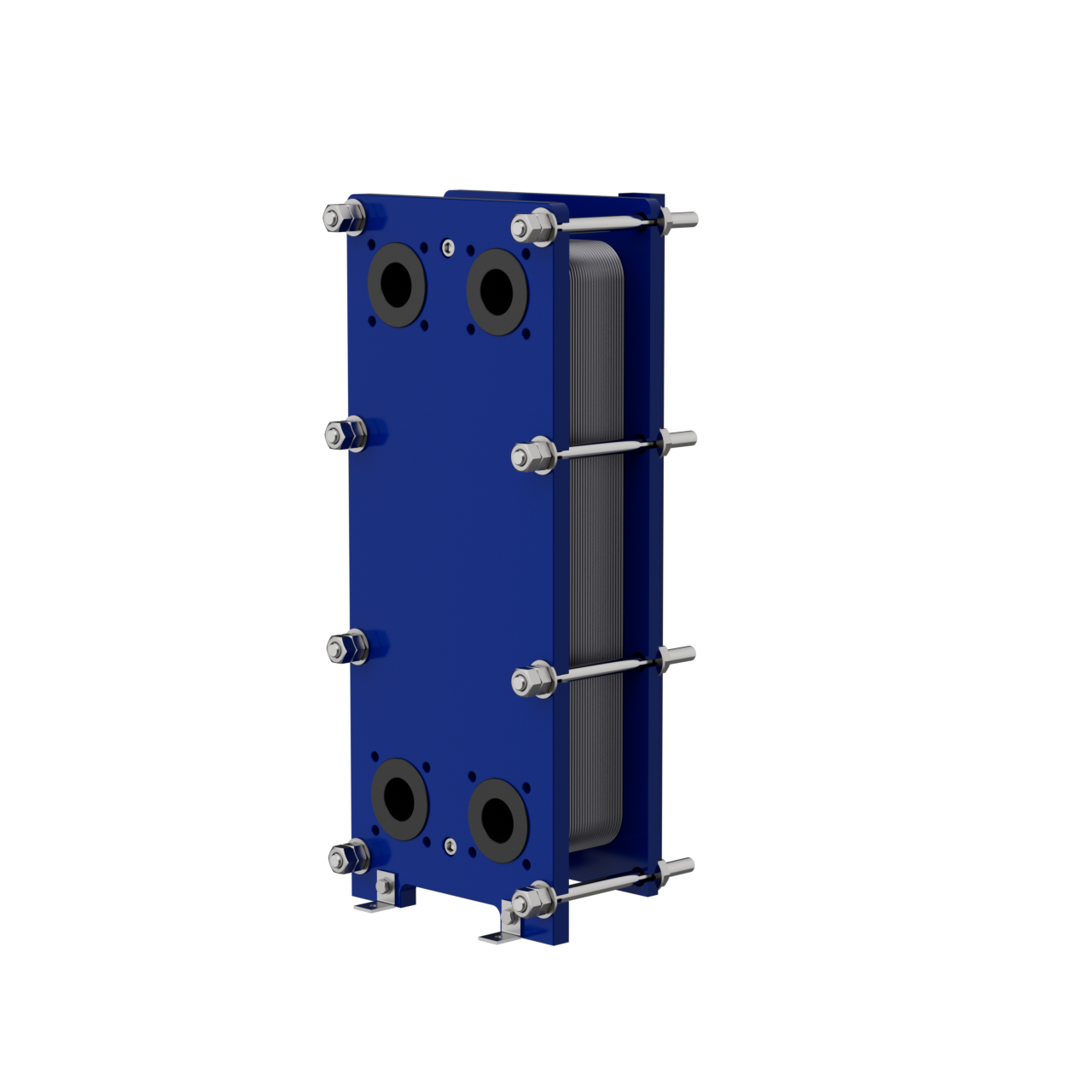

Free Flow Plate Heat Exchangers

For Fibers, Particles, and Highly Viscous Products

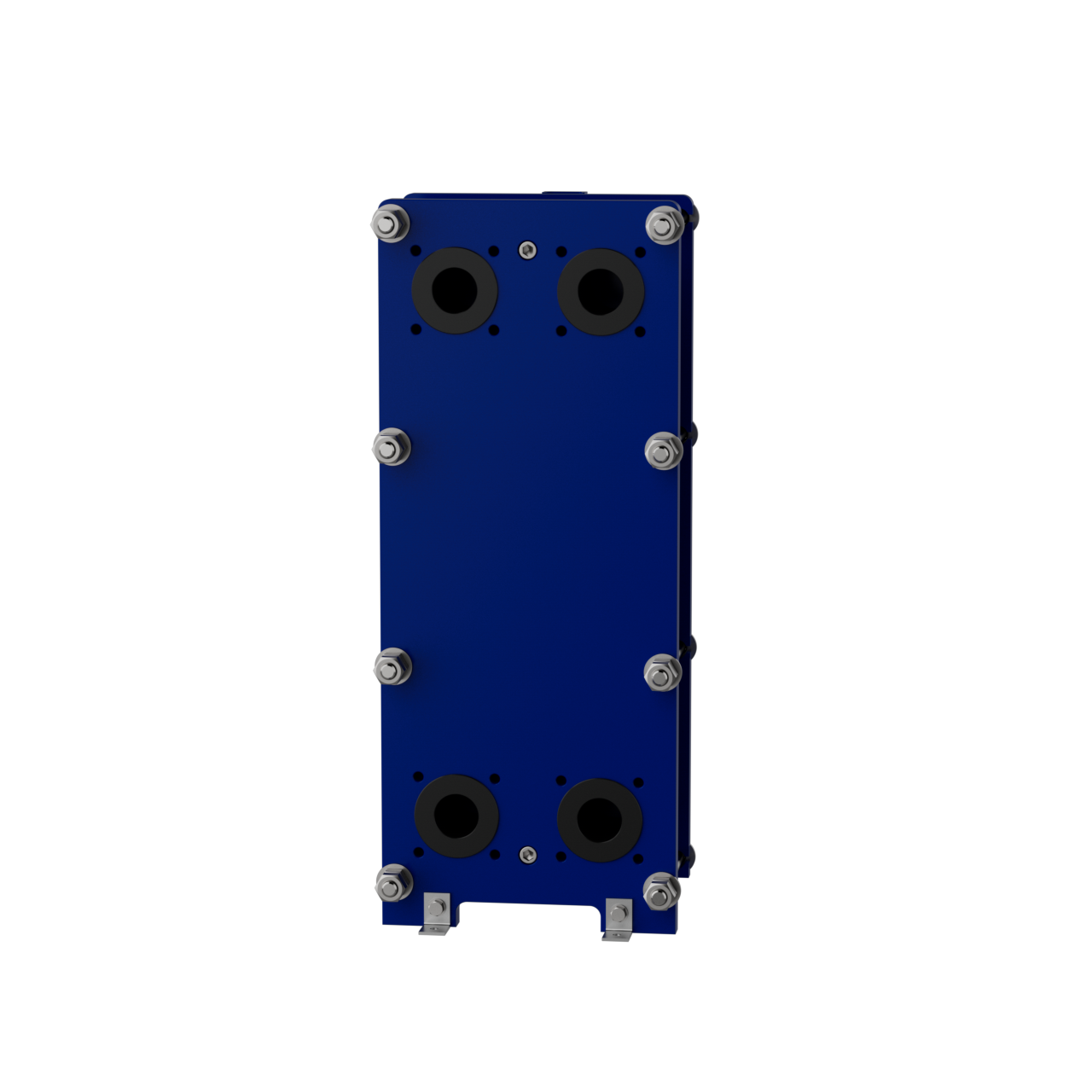

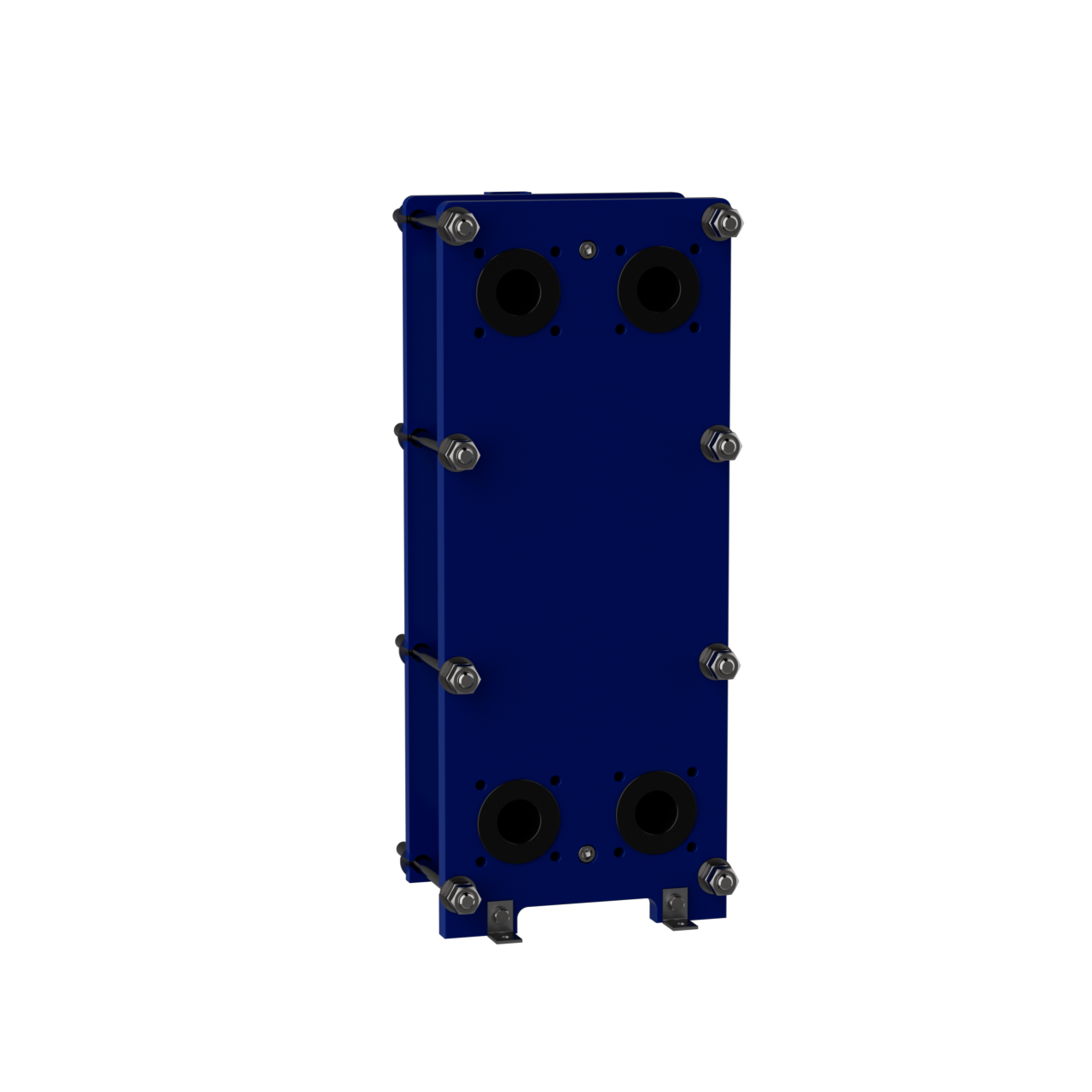

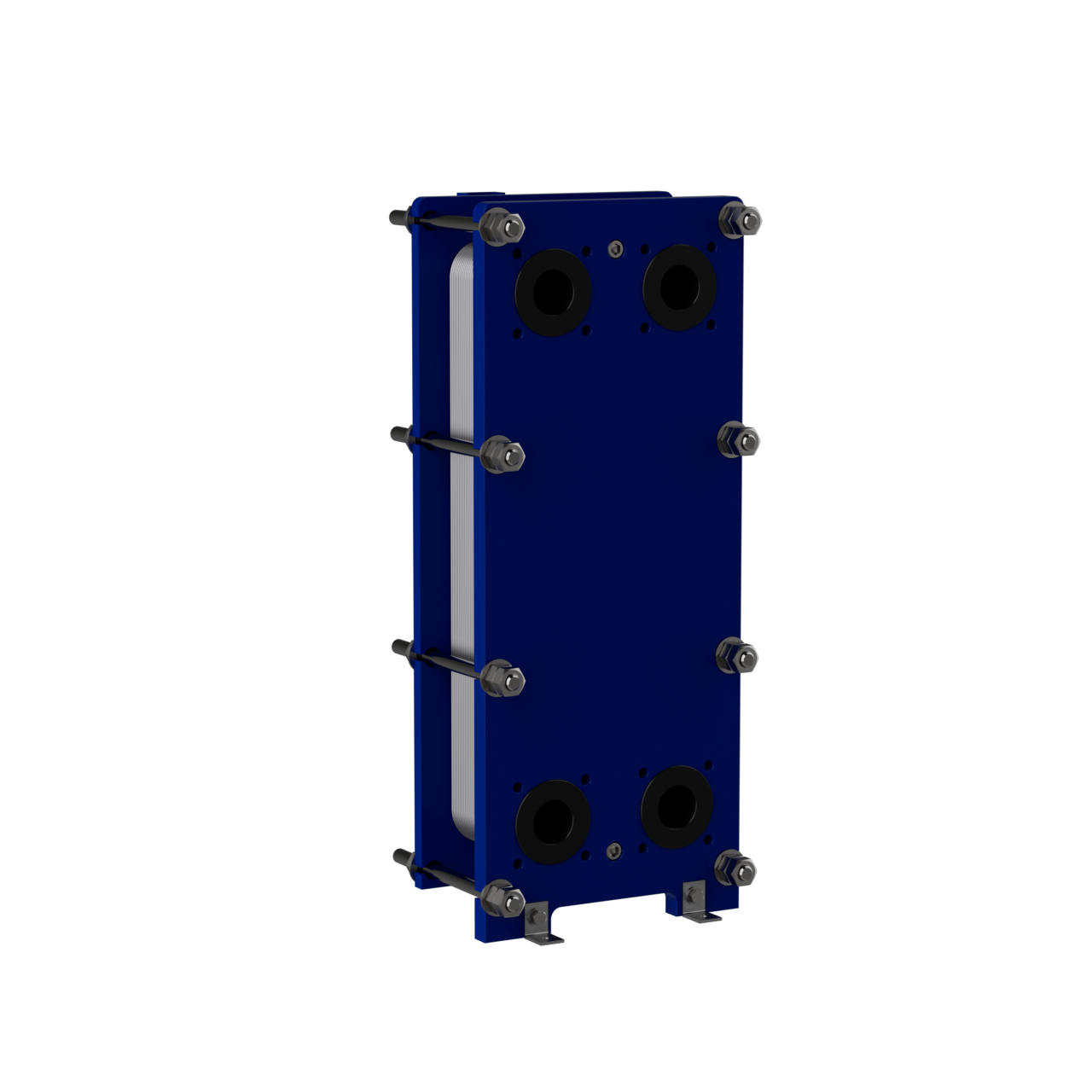

The new Free Flow plate heat exchanger series from ZILONIS Energy Solutions is ideal for difficult media with solids, particles, fibers, and highly viscous products. The Free Flow plate pattern is designed for special tasks where conventional plate heat exchangers typically have a higher risk of fouling or clogging.

For Fibers, Particles, and Highly Viscous Products

The new Free Flow plate heat exchanger series from ZILONIS Energy Solutions is ideal for difficult media with solids, particles, fibers, and highly viscous products. The Free Flow plate pattern is designed for special tasks where conventional plate heat exchangers typically have a higher risk of fouling or clogging.

The Free Flow plate series focuses on reliability and high performance. If the plate heat exchanger is unsuitable for the operating media, maintenance intervals increase and the risk of fouling rises.

Optimized Flow Distribution

Optimized flow distribution reduces fouling and uneven temperature zones, maintaining high performance over time without unnecessary energy losses, maintenance costs, or unplanned downtimes.

Features

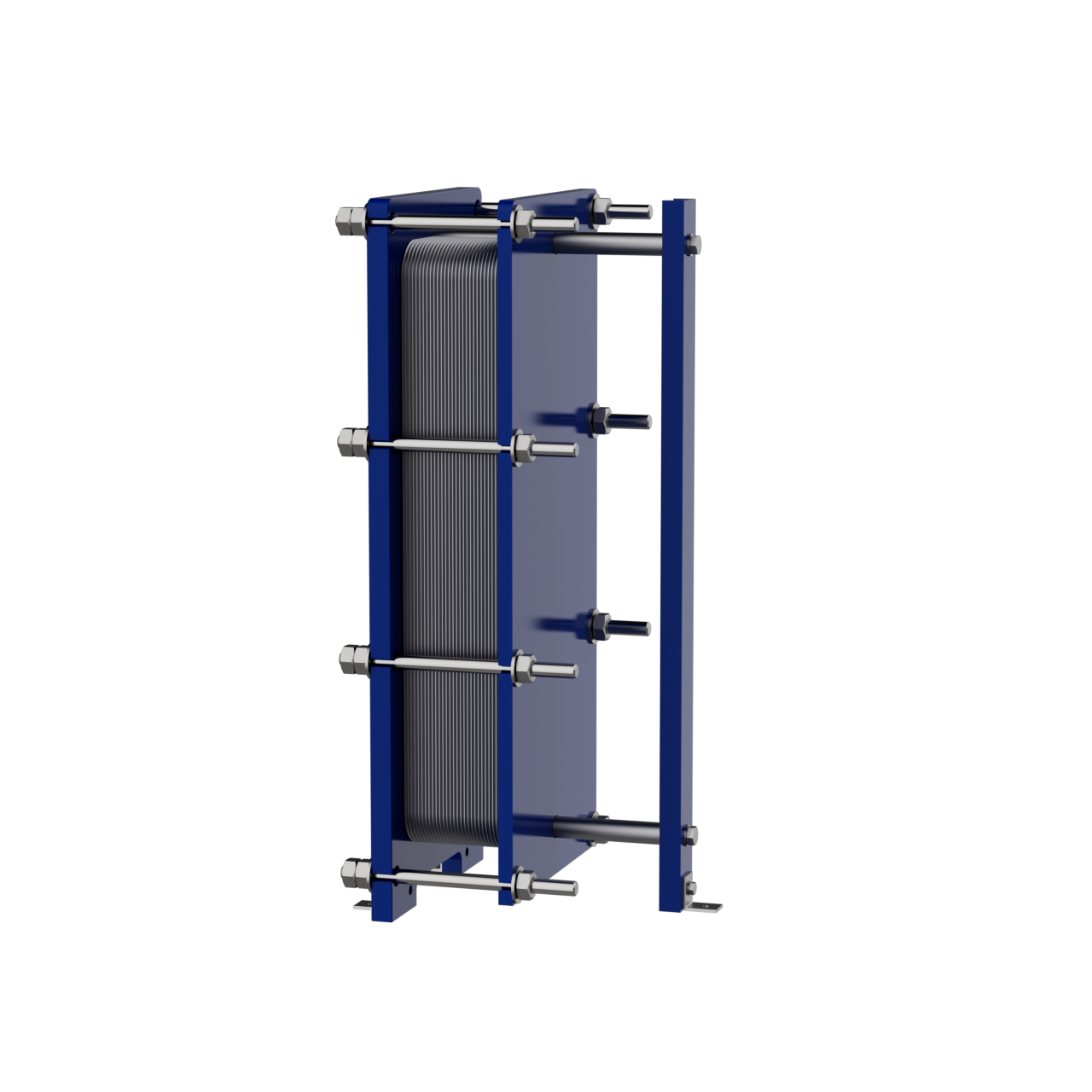

Every detail has been carefully developed to ensure optimal performance, reduced maintenance costs, and reduced downtime:

• Compact design • Lock gasket system • Gentle product handling • Design pressure up to 10 bar • Operating temperature up to 180°C • Suitable for products with solid particles • Fixed bolt head • Lifting device • Liner • Lock washer

Advantages

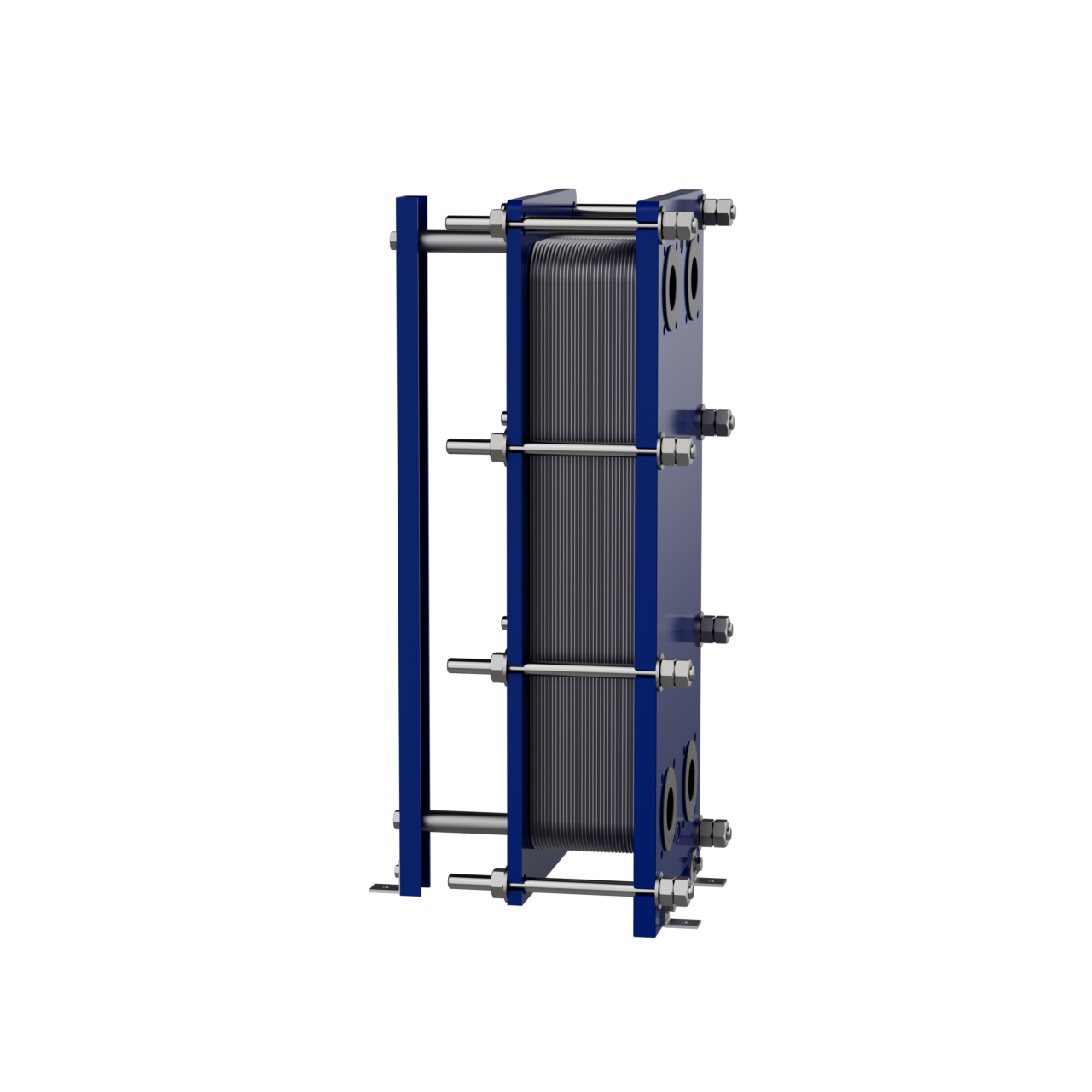

• Designed for CIP cleaning • Easy assembly and cost-effective • Developed to combat fouling • Clog-resistant • The inlet area is designed for distribution and flow across the plate • No dead spots on the plate • Wide channels enable efficient flow and heat transfer

Applications

Dairy/food/beverage industry • Sugar industry • Biogas industry • Wastewater industry • Pulp and paper industry • Mining

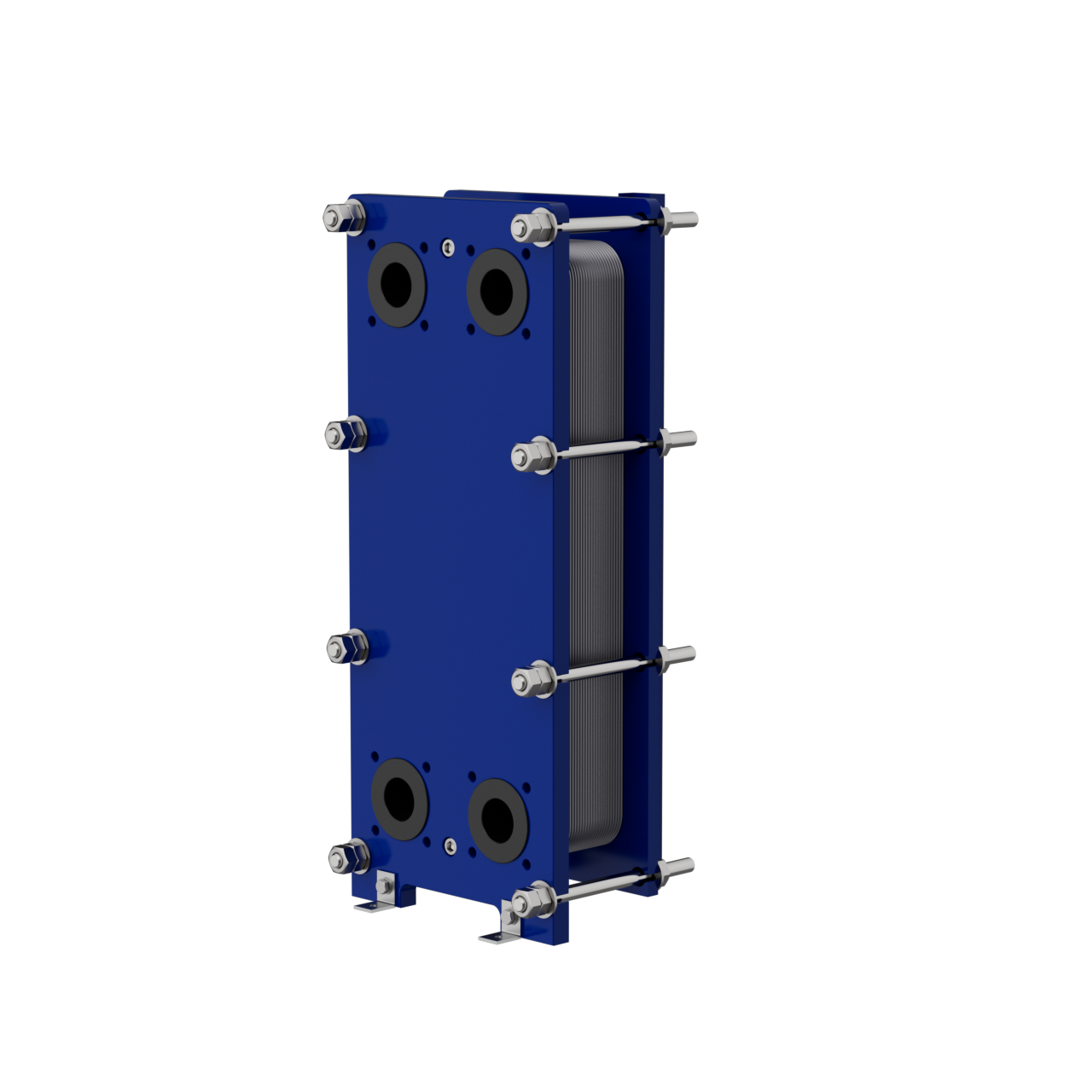

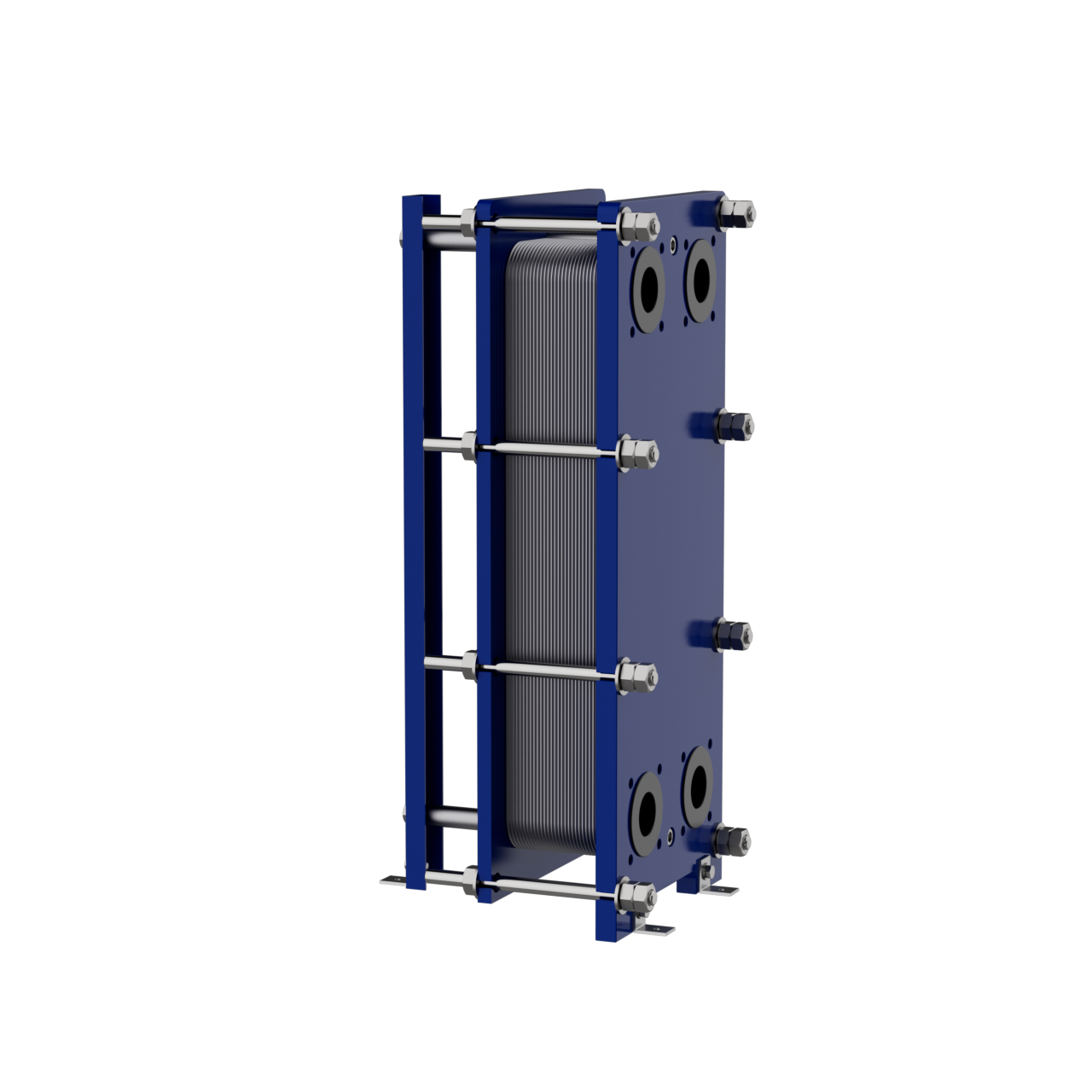

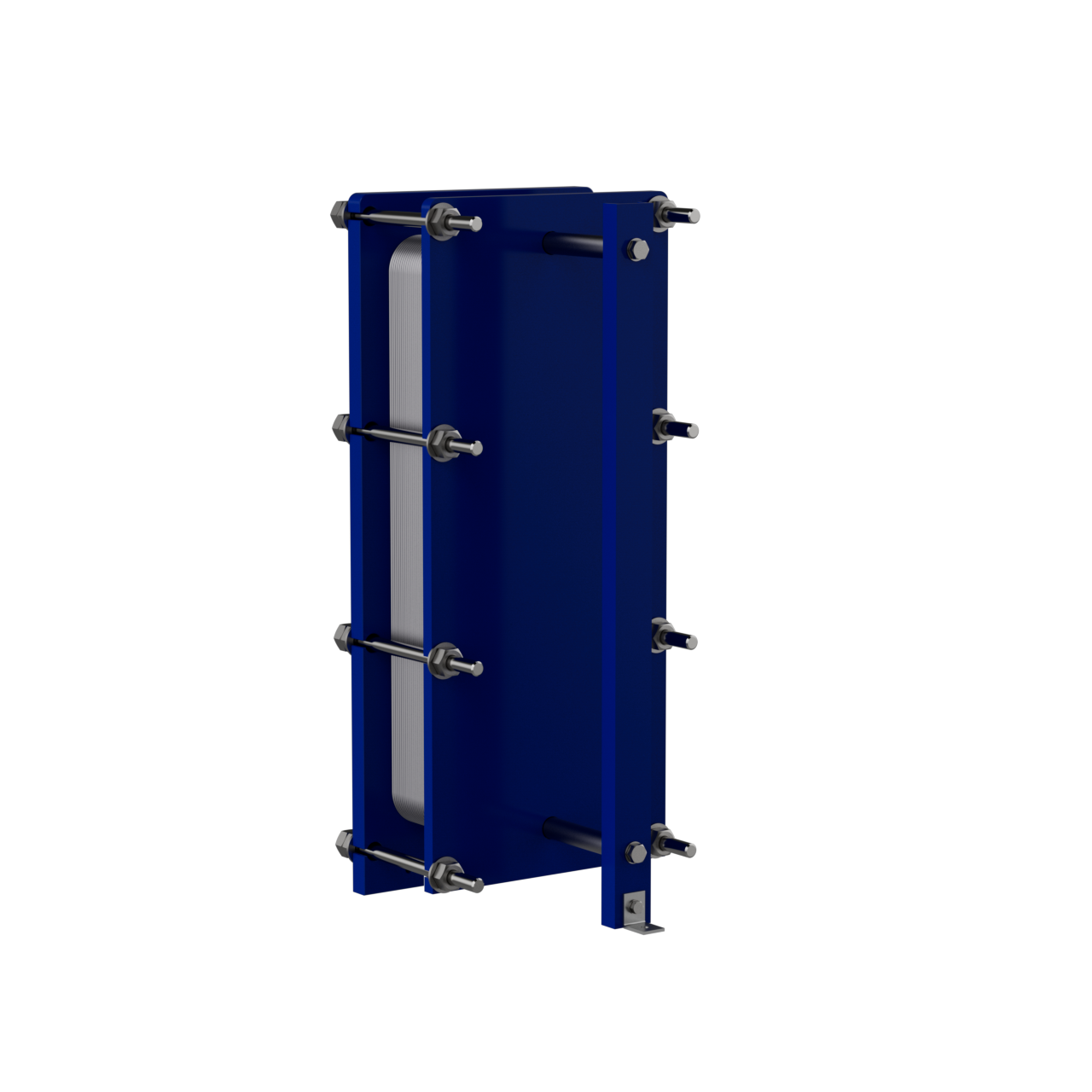

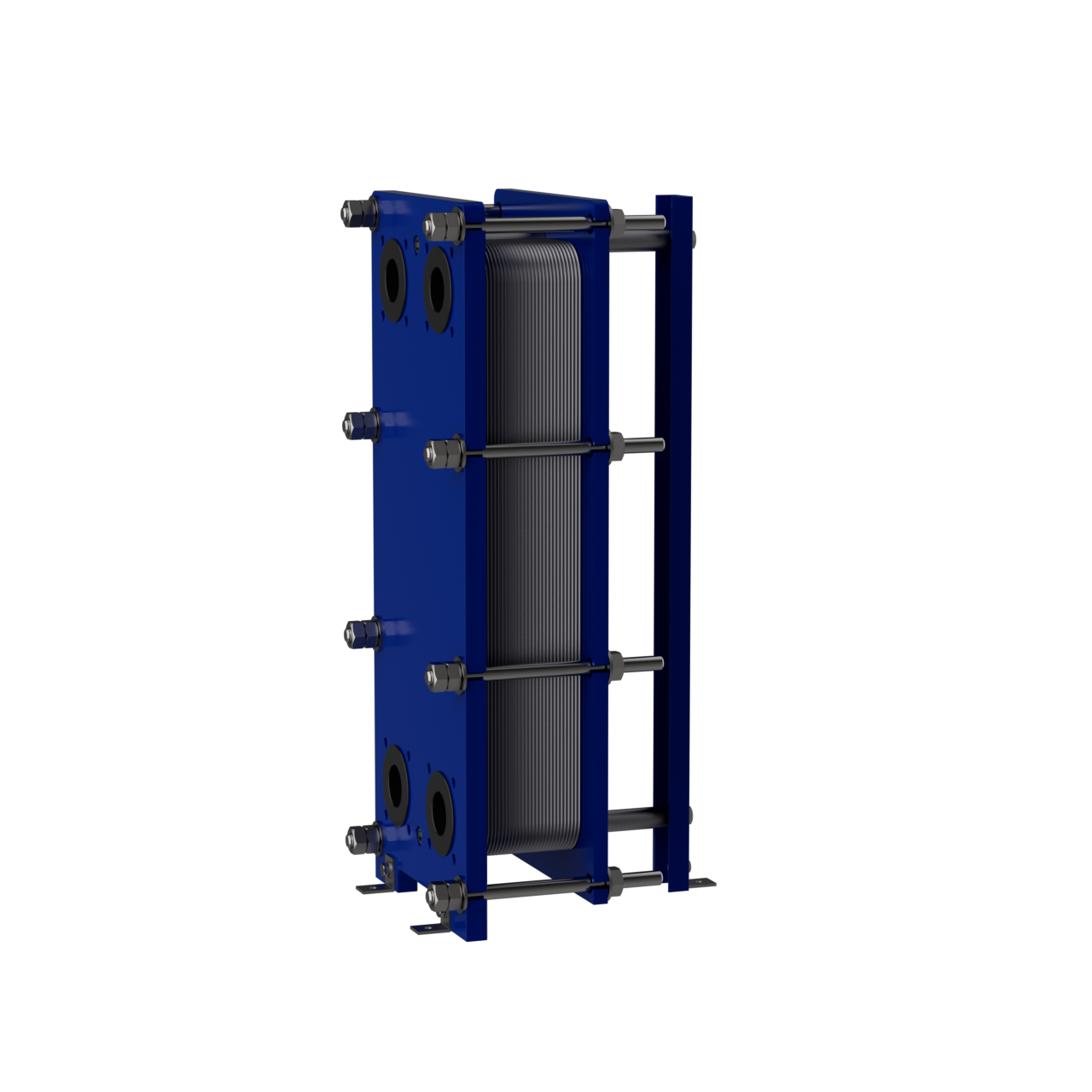

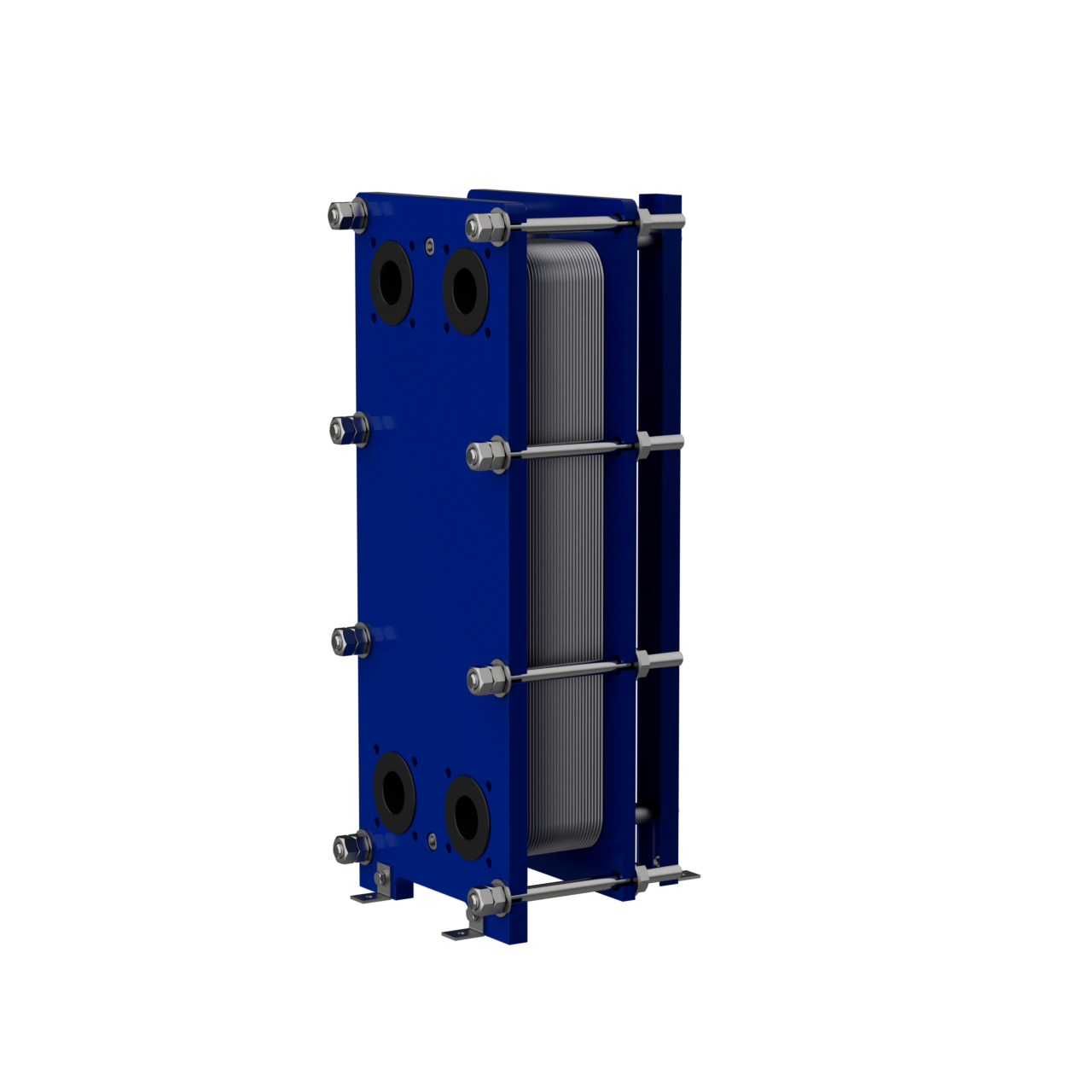

Plates

The wide channels provide sufficient space for difficult media to flow freely. The horizontal wave pattern maintains no plate contact points in the flow direction, ensuring gentle treatment of the source product. The distance between heat transfer plates is up to 12 mm gap, depending on plate type.

The Free Flow plate heat exchanger SFF151 and SFF301 are specially designed for the mixture of viscosity and flow. The design consists of two different plate patterns: 'HIGH' and 'LOW', which can be optionally mounted for 12/6 mm or 9/9 mm plate spacing.

Technical Specifications

Gaskets: Click-on gasket – an adhesive-free sealing system • Materials: NBR, EPDM and Viton (others on request)

Frame: Painted frame RAL 5010 (available in other colors)

Construction codes: EN13445 • ASME Section VIII, Div. 1

Design pressure: Painted frames 1.0 MPa (145 PSI), max. differential pressure 156 bar • Stainless steel frames 1.0 MPa (145 PSI)

Plate material: AISI 304/316 and titanium (other materials on request)

Accessories: Drip tray • Insulation jackets • Safety cover • Wrench • Foundation feet

ANWENDUNGSSPEZIFISCH

Ihre Märkte sind unsere Märkte. Jährlich verlassen über tausend Produkte ZILONIS, die weltweit eingesetzt werden, um die anspruchsvollsten Herausforderungen zu meistern.

/chemie-und-petrochemie.jpg)

/energietechnik.jpeg)

/pharmaindustrie.jpg)

/gebaeudetechnik.jpeg)

/holz-und-papierindustrie.jpeg)