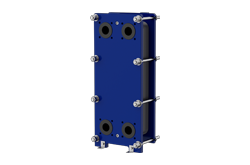

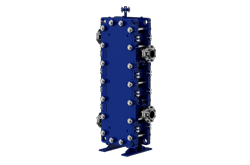

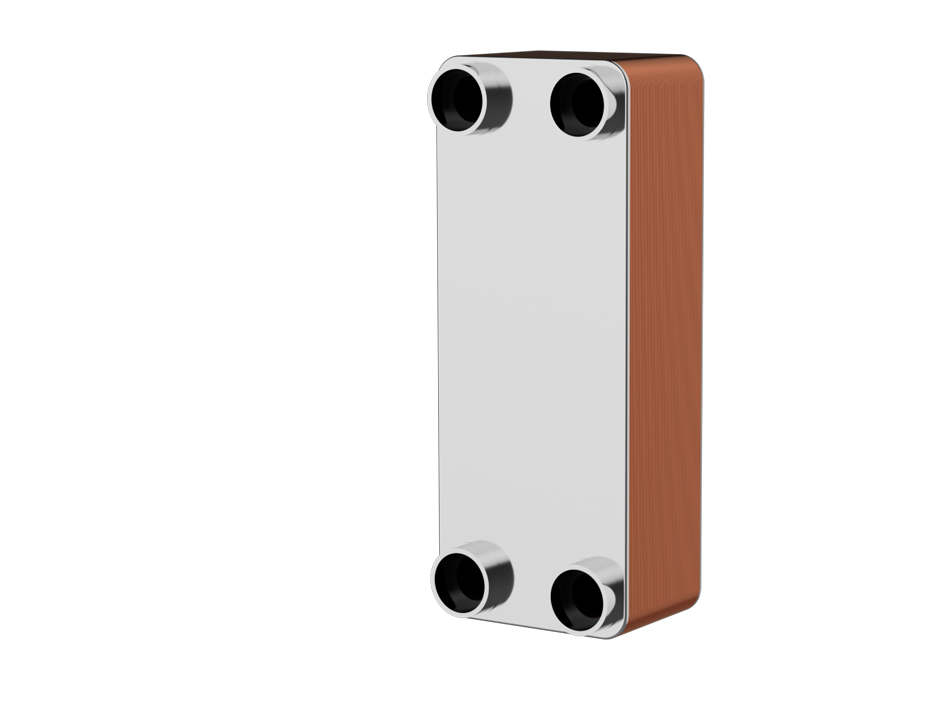

BRAZED PLATE HEAT EXCHANGERS

Efficient solutions from ZILONIS Energy Solutions.

ZILONIS Energy Solutions focuses on the performance of brazed plate heat exchangers. Thanks to state-of-the-art technologies and decades of experience, the highest quality, cost efficiency and reliability are guaranteed with every one of our products.

Construction

Every detail of our heat exchangers is carefully designed to ensure optimum performance, minimize maintenance costs and reduce downtime.

As sustainability is a core concern for us our appliances are not only energy efficient, but also environmentally friendly.

Our brazed heat exchangers consist of a package of thin corrugated metal plates surrounded by two thicker stabilizing plates. During a vacuum brazing process, a thin copper foil melts between the metal plates and seals the heat exchanger.

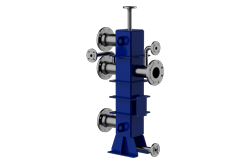

Each solution is customized to our customers' requirements to ensure optimal pressure drop and flow. This not only achieves high energy efficiency, but is also environmentally friendly. The number of plates and the size of the heat exchangers are determined according to the specific requirements.

The design of the corrugated plates optimizes heat transfer by providing a large yet compact overall surface area for transferring heat from one fluid or gas to another. The plates are tailored to temperature requirements and capacities to ensure optimal performance. Through these optimizations, we aim to ensure that our plate heat exchangers not only meet but exceed our customers' expectations.

At ZILONIS Energy Solutions, we strive to provide energy-efficient, eco-friendly, and reliable solutions for your heat exchange needs.

Every detail is carefully designed to ensure optimal performance, reduce maintenance costs, and decrease downtime.

One of our focus areas is sustainability and therefore it is important that the units are energy-efficient and environmentally friendly.

Construction

The Brazed heat exchanger is constructed by a package of thin corrugated metal plates, surrounded by two thicker stabilizing plates. A thin copper foil placed between each of the thin metal plates melts and seals the brazed plate heat exchanger during a vacuum brazing process.

We calculate each solution based on the customer’s requirements to ensure an ideal pressure drop and flow rate. And at the same time, the unit becomes energy-efficient and environmentally friendly. Based on the individual task, we also determine the number of plates and the size of the brazed heat exchangers.

Advantages

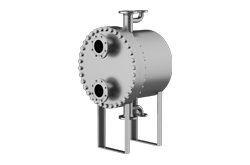

Technical specifications:

- Plate material: AISI 316

- Brazing material: Copper

- Design pressure: 25 and 40 bar (362 and 580 PSI)

- Temperature: -100 to 185˚C (-148 to 365˚F)

- Connections: between ¾” and DN100

General:

- High performance & reliability

- Lower operating costs

- Easy installation

- Increased energy efficiency

- Low weight

- Robust and compact design

- High flexibility

- Wide range of applications

- Certificates and standards

Technical specifications:

- Plate material: AISI 316

- Brazing material: Copper

- Design pressure: 25 and 40 bar (362 and 580 PSI)

- Temperature: -100 to 185˚C (-148 to 365˚F)

- Connections: between ¾” and DN100

BPHE Benefits:

- Lower operating costs

- Cost-effective

- Easy assembly

- Increased energy efficiency

- Low weight

- Compact design

- High flexibility

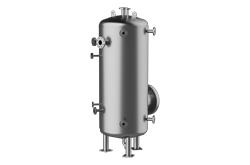

Designed to meet your needs

Our extensive range ensures that we offer the best solution at the best price and can combine several different heat exchanger types if required to ensure that you get the best possible solution.

INDUSTRIES

Food

Chemical And Petrochemical

Power Engineering

Building Services Engineering

Pharmaceutical

Wood and Paper

Oil and Gas

Marine

Newsletter

Product and technological news