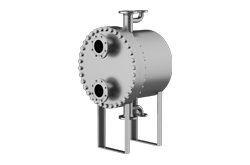

BUFFER TANK

The buffer tanks from ZILONIS Energy Solutions are individually designed and manufactured according to your specifications. With us you do not get simple serial tanks but individual solutions for your needs. We are flexible in terms of diameter and overall height and we also manufacture the internals for stratification exactly according to your specifications - whether nozzle pipes, pipe bends, baffle plates or stratification plates. On request, our buffer storage tanks are equipped with a manhole as an inspection opening and can also be coated both inside and outside according to your specifications.

Description of buffer tanks

Our buffer tanks are manufactured according to customer specifications and individual drawings.

All our buffer storage tanks are calculated and manufactured according to the AD2000 regulations, even if they fall under the PED 2014/68/EU Art. 4.3. Therefore, at your request, we can also equip the buffer storage tanks with a CE mark without much effort.

In cooperation with the pre-testing bodies of the notified bodies and various engineering offices, we can also prepare further calculations for your buffer storage tank on your request, e.g. stability verifications for earthquake zones or wind loads, nozzle loads or threshold loads.

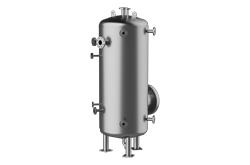

We process all common materials of boiler construction. In addition to carbon steels, we can also convert our workstations for stainless steel and manufacture our products as stainless steel tanks. We process materials such as

- P265GH

- S235JR+N

- P235GH

- P250GH

- P355NH

- 1.4571

- 1.4404

- 1.4541

- 1.4301

In addition, we can also supply all vessels made of equivalent ASME materials (e.g. SA516 Gr.60).

A great advantage of our production is the flexible handling of different wall thicknesses. A 100 liter container with a wall thickness of 5mm is just as much a part of our production program as a large container with a capacity of 80,000 liters.

- Wall thicknesses from 4mm to 20mm

- Diameter from pipe size to 3200mm

- Containers up to a unit weight of 12 tons

Thanks to modern calculation programs, we determine the required wall thicknesses for your container as early as the quotation phase and can design the container precisely during the project phase. All containers are designed and calculated in accordance with AD2000 or EN 13445 regulations. The drawings and calculations produced are submitted to a notified body (e.g. TÜV) and checked in advance when the order is placed, at no additional cost to you as the customer.

Our containers are manufactured individually, which enables us to check every nozzle position and make spontaneous changes during production. As a traditional family business, our flexibility is your advantage. Do you need to change the nozzle positions or additional attachments such as pipe supports at short notice, even though the container is already in the production process? We fulfill your wishes and can also make spontaneous changes during production.

We process all common materials of boiler construction. In addition to carbon steels, we can also convert our workstations for stainless steel and manufacture our products as stainless steel tanks. We process materials such as

- P265GH

- S235JR+N

- P235GH

- P250GH

- P355NH

- 1.4571

- 1.4404

- 1.4541

- 1.4301

In addition, we can also supply all vessels made of equivalent ASME materials (e.g. SA516 Gr.60).

A great advantage of our production is the flexible handling of different wall thicknesses. A 100 liter container with a wall thickness of 5mm is just as much a part of our production program as a large container with a capacity of 80,000 liters.

- Wall thicknesses from 4mm to 20mm

- Diameter from pipe size to 3200mm

- Containers up to a unit weight of 12 tons

Thanks to modern calculation programs, we can already determine the necessary wall thicknesses for your pressure vessel in the quotation phase. This allows us, in coordination with your wishes, to design the vessel correctly and calculate it exactly already in the project phase. All pressure vessels are designed and calculated by us according to the AD2000 regulations or EN 13445.

The drawings and the verifiable calculations prepared by us when an order is placed are then submitted to the notified body (e.g. TÜV) and pre-checked. For you as a customer, this is a service which is included in the total price of the vessel and - just like the pressure test - does not incur any additional costs.

All pressure vessels from ZILONIS Energy Solutions GmbH & Co. KG are individually planned, drawn and manufactured. This means that you can check every nozzle position or connection size before the start of production and adapt it to your required specifications at the construction site. As a traditional family business, our flexibility is your advantage. Do you need a short-term change of nozzle positions or additional attachments such as pipe supports, even though the vessel is already in the production process? We always try to meet the wishes of our customers and can also make spontaneous changes during production.

Optional: Tank insulation

Optionally, we can also supply our storage tanks with insulation. It does not matter for us whether you need a soft foam insulation (PU soft foam or fleece insulation according to DIN 4102 B1) for the interior or a mineral wool insulation with sheet metal jacket for the exterior installation.

Please contact us! Together with our partners from the region we can offer an insulation for your needs.

INDUSTRIES

Food

Chemical And Petrochemical

Power Engineering

Building Services Engineering

Pharmaceutical

Wood and Paper

Oil and Gas

Marine

Newsletter

Product and technological news