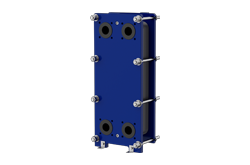

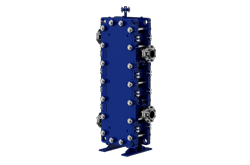

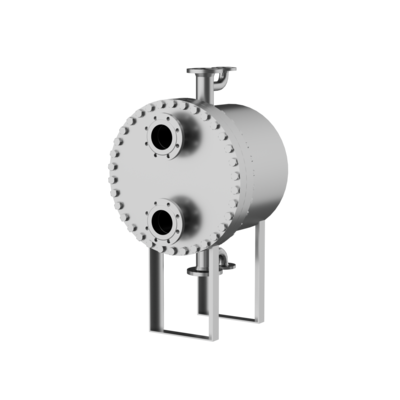

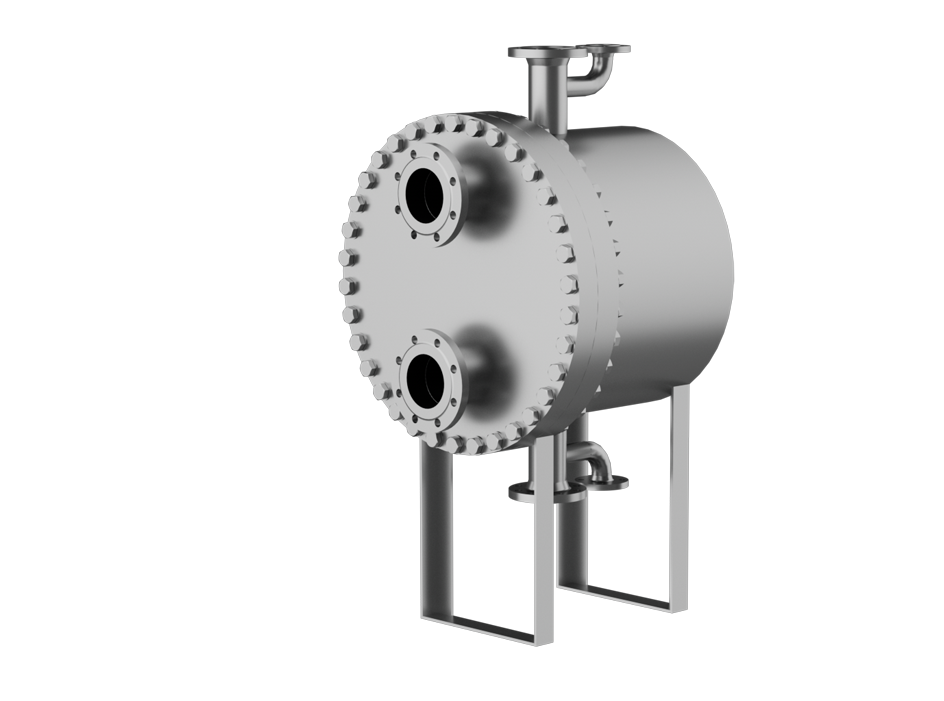

PLATE AND SHELL

Plate & Shell heat exchangers are the top solution for applications with high pressure and temperature requirements. Their robust construction and fully welded plate pack ensure exceptional resistance to aggressive media and minimize the risk of leakage. Learn more about their advantages for your specific requirements.

Description of Plate and Shell

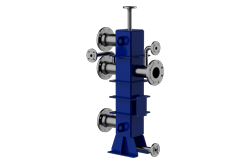

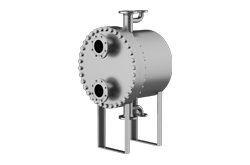

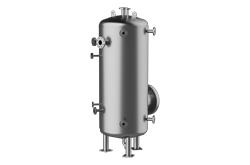

Plate & Shell heat exchangers offer first-class solutions for applications with high pressure and temperature requirements. Their fully welded plate pack ensures excellent resistance to aggressive media, which significantly reduces the risk of leaks. These heat exchangers also enable effortless cleaning of the media circuits and guarantee high energy efficiency, resulting in low operating costs. Compared to conventional shell & tube heat exchangers, they are space-saving and lighter.

Our Plate & Shell heat exchangers combine the advantages of shell-and-tube and plate heat exchangers (Plate) in cylindrical shells (Shell). They maintain the operating pressure and temperature of shell & tube heat exchangers while offering the high efficiency of plate heat exchangers. With this innovative solution, you benefit from the best features of both technologies.

Advantages at a glance:

- High performance in a small area

- Excellent leakage protection

- Ideal for use with aggressive media

- Robust corrosion resistance

- Temperature resistance up to 500°C

- Operating pressure up to 400 bar

- Maximum energy efficiency

- Low total cost of ownership

- Flexible connection sizes from DN 20 to DN 1000

Our Plate & Shell heat exchangers offer you the perfect solution for demanding applications that require maximum performance and reliability.

INDUSTRIES

Food

Chemical And Petrochemical

Power Engineering

Building Services Engineering

Pharmaceutical

Wood and Paper

Oil and Gas

Marine

Newsletter

Product and technological news