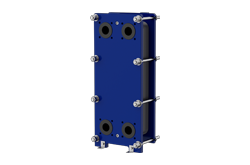

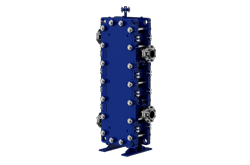

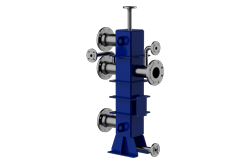

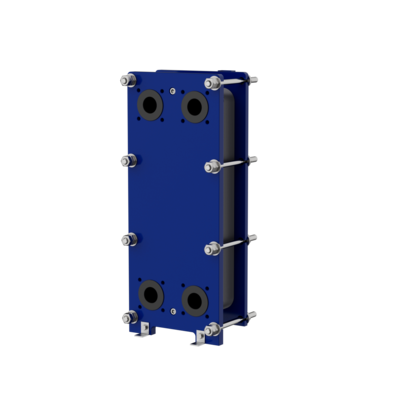

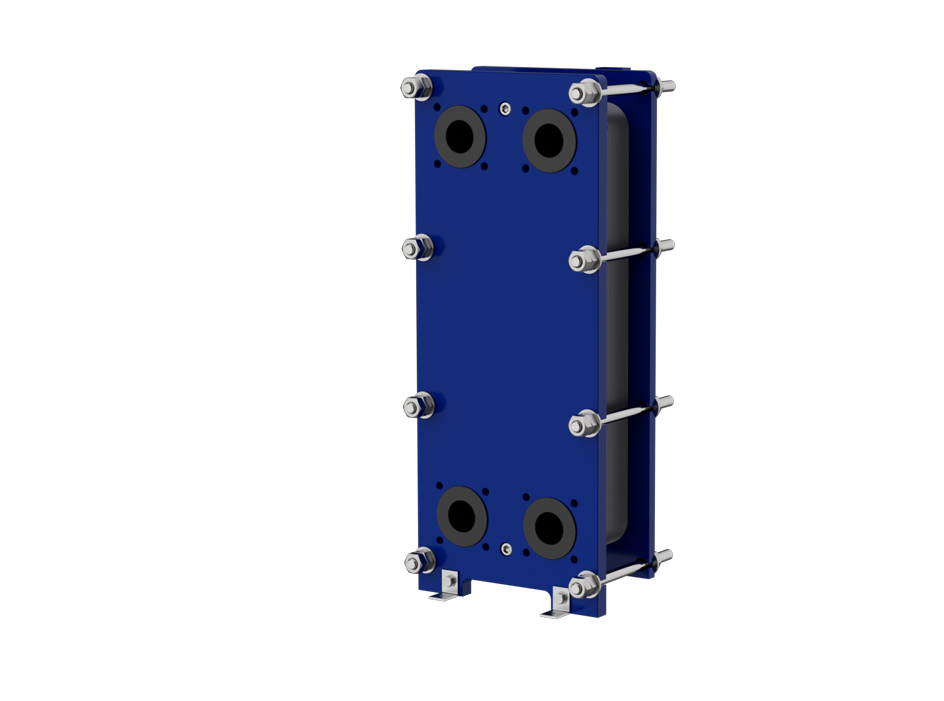

PLATE HEAT EXCHANGER

Our units are optimised to meet specific temperature demands and capacities in HVAC, industrial or hygienic applications.

Depending on the quality of fluids used ZILONIS Energy Solutions gasketed plate heat exchangers are available in a range of high quality plate materials including stainless steel, titanium and nickel to ensure corrosion resistance.

- Technology and quality

- Very competitive pricing

- Short lead times

- Advanced supply chain capability

- Traceable production processes ensure quality

- Full monitoring of raw materials

Features

Every detail is carefully designed to ensure optimal performance, reduced maintenance costs and decreased downtime:

- Compact design

- High flexibility

- Lock gasket system

- Gentle product handling

- Design pressure up to 25 bar

- Operating temperature: up to 180° C

- Leak chamber

- Fixed bolt head

- Lifting lug

- Lining

- Lock washer

Technical Specification

Special Benefits

- Connections from DN25 to DN400

- (Frames designed according to PED 2014/68/EU (EN13445) and ASME sec VIII, Div. 1 construction standards)

- Plate materials: AISI 304/316, titanium, SMO. Other materials available upon request

- Gasket materials: EPDM, NBR and Viton.

- Plate heights up to 3.5 m

- Flow rates up to 7200 m³/t (31,700 gpm)

- Working pressure up to 25 bar (363 psi)

- A short pay-back period on investment

- High thermal efficiency due to knowledge, experience and the design

- Compact design and simple installation

- Each heat exchanger is individually designed for the heat load, flow

rate and pressure drop limitations of the specific application - Energy efficiency solutions has the power to protect the environment and create greener solutions

- Lower operating costs

- Cost-effective

- Easy assembly

- Easy cleaning

- Dead spots, that cause corrosion and fouling are

eliminated

Applications

Accessories

Frame

- HVAC

- Heat recovery

- Industrial

- Food & beverages

- Sugar industry

- Chemicals

- Marine

- Mining

- Drip tray

- Insulation jackets

- Safety cover

- Assembling spanner

- Foundation feet

- Painted frame, RAL 5010 (available in other colours)

- Stainless steel frame

Design Pressure

Construction Standards

Plate Material

- Painted frames: 1.0/1.6/2.5 MPa (145/232/362 PSI)

- Stainless steel: 1.0/1.6 MPa (145/232 PSI)

- EN13445

- ASME sec VIII, Div. 1

- AISI 304/316 and titanium

- Other materials available on request

Technical Specifications

- Connections from DN25 to DN400

- (Frames designed according to PED 2014/68/EU (EN13445) and ASME sec VIII, Div. 1 construction standards)

- Plate materials: AISI 304/316, titanium, SMO. Other materials available upon request

- Gasket materials: EPDM, NBR and Viton.

- Plate heights up to 3.5 m

- Flow rates up to 7200 m³/t (31,700 gpm)

- Working pressure up to 25 bar (363 psi)

Special Benefits

- A short pay-back period on investment.

- High thermal efficiency due to knowledge, experience and the design

- Compact design and simple installation

- Each heat exchanger is individually designed for the heat load, flow

rate and pressure drop limitations of the specific application. - Energy efficiency solutions has the power to protect the environment and create greener solutions.

Advantages

Expandable – saves time and money

High efficiency – due to pressed patterns in the plates and the relative narrow gaps, very high turbulence is achieved at relative low fluid velocity

Multiple duties in a single unit – can be built in sections, separated with divider plates or more complicated divider frames

Less fouling – smooth plate surface reduces fouling

Easy to clean – remove the tie bolts and slide back the moveable frame part, and then the plate pack can be inspected and cleaned

Expandable – saves time and money

High efficiency – due to pressed patterns in the plates and the relative narrow gaps, very high turbulence is achieved at relative low fluid velocity

Close approach temperature – possible to reach close approach temperatures

Multiple duties in a single unit – can be built in sections, separated with divider plates or more complicated divider frames

Less fouling – smooth plate surface reduces fouling

Easy to clean – remove the tie bolts and slide back the moveable frame part, and then the plate pack can be inspected and cleaned

Products

ZILONIS Energy Solutions offers a wide range of gasketed plate heat exchangers that increase sustainability through their energy-efficient design. With a compact frame and innovative plate patterns, they are suitable for a variety of industries including heating, cooling, heat recovery, condensation and evaporation.

Our aim is to continually expand and improve the range by introducing new performance criteria and offering more flexibility.

The design of the corrugated plates maximizes heat transfer through a large-area, yet compact design that allows heat to be efficiently transferred from one liquid or gas to another. The plates are shaped in a corrugated herringbone pattern to create an ideal turbulent flow and make the most of the available pressure drop.

Optimized flow distribution reduces fouling and uneven temperature zones, maintaining performance over time without unnecessary energy loss, high maintenance costs or unplanned shutdowns.

Our plates are available in different press shapes, chevron pattern angle variations and different waveforms, carefully selected to ensure optimum performance depending on the application. Each product range has its own plate features tailored to its specific requirements.

SFF100 Series

The SFF100 series has an inlet and outlet socket diameter of 96mm.SF30 Series

The SF30 series has an inlet and outlet socket diameter of 36mm.SF50 Series

The SF50 series has an inlet and outlet socket diameter of 60mm.SF55 Series

The SF55 series has an inlet and outlet socket diameter of 60mm.SF60 Series

The SF60 series has an inlet and outlet socket diameter of 67mm.SF70 Series

The SF70 series has an inlet and outlet socket diameter of 70mm.SF80 Series

The SF80 series has an inlet and outlet socket diameter of 85mm.SF150 Series

The SF150 series has an inlet and outlet socket diameter of 150mm.SF200 Series

The SF200 series has an inlet and outlet socket diameter of 201mm.SF250 Series

The SF250 series has an inlet and outlet socket diameter of 250mm.SF300 Series

The SF300 series has an inlet and outlet socket diameter of 314mm.SF400 Series

The SF400 series has an inlet and outlet socket diameter of 412mm.INDUSTRIES

Food

Chemical And Petrochemical

Power Engineering

Building Services Engineering

Pharmaceutical

Wood and Paper

Oil and Gas

Marine

Newsletter

Product and technological news