SHELL AND TUBE HEAT EXCHANGER

Efficient heat transfer for a wide range of applications

Our shell and tube heat exchangers are designed to transfer heat extremely efficiently between liquids. Thanks to robust designs, we always guarantee optimum heat output.

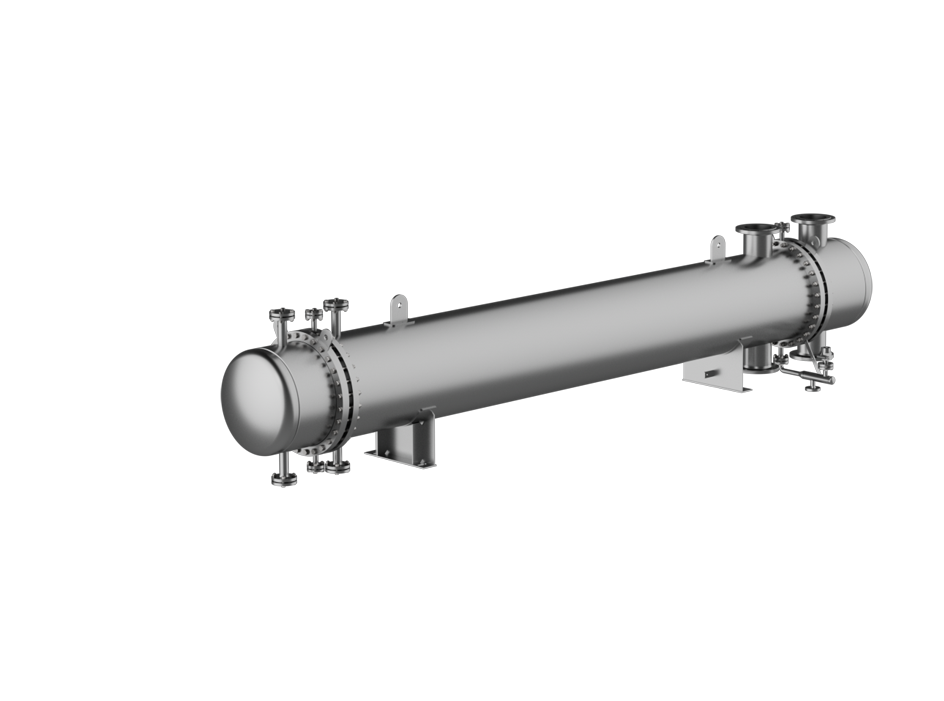

Definition and function of shell and tube heat exchangers

Heat exchangers are devices that are used to transfer heat from a liquid or gaseous fluid through a partition wall to another fluid. In many applications, shell and tube heat exchangers are the most common solution. Thanks to our optimally matched designs and materials, we not only offer a wide range of applications, but also outstanding thermal performance. This means that you always benefit from a cost-efficient and reliable solution.

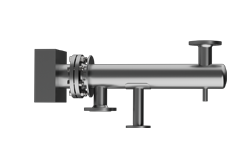

Due to their usually simple design, high heat transfer capacity and easy inspection, shell and tube heat exchangers are not only widely used in chemical plants. A shell and tube heat exchanger essentially consists of a cylindrical tank (shell) into which a tube bundle is installed. This bundle is made up of tubes arranged in parallel, which are welded into round plates with holes, the tube sheets.

Shell and tube heat exchangers have at least two separate chambers: essentially the tube chamber and the shell chamber. One fluid flows through the tube bundle (tube chamber), while the other fluid flows between the tubes in the shell space. Baffles and guide plates in the shell space deflect the fluid and thus improve heat exchange. When heating steam is used, it usually flows around the tubes in the shell space, while liquids or cooling liquids to be cooled are guided through the tubes. In special cases, e.g. with very high steam pressures, this can also be routed through the tubes.

Our heating condensers, sometimes referred to as condensers, play a vital role in converting gaseous media into the liquid state. They are crucial components for achieving this transition smoothly.

Steam generators are of paramount importance, particularly when converting liquid media into the gaseous state. This is essential for applications such as feed water treatment and power transmission within the energy sector.

At ZILONIS, our safety heat exchangers feature double tubes welded into double tube plates, creating a secure space. This design ensures the highest safety standards for your specific applications.

Our sterile heat exchangers, equipped with single tubes and double tube

plates, prevent media mixing, even in cases of tube/tube sheet weld joint

leaks. This critical feature helps maintain the purity of your processes.

INDUSTRIES

Food

Chemical And Petrochemical

Power Engineering

Building Services Engineering

Pharmaceutical

Wood and Paper

Oil and Gas

Marine

Newsletter

Product and technological news