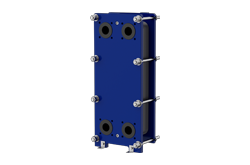

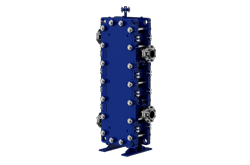

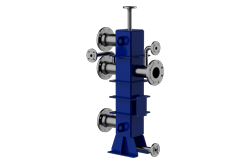

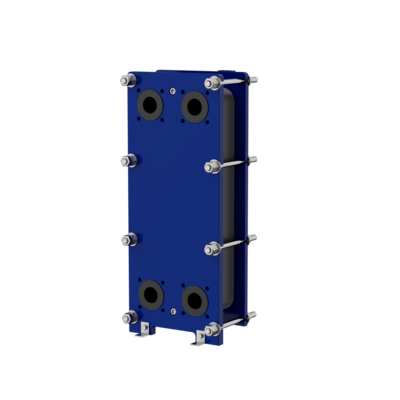

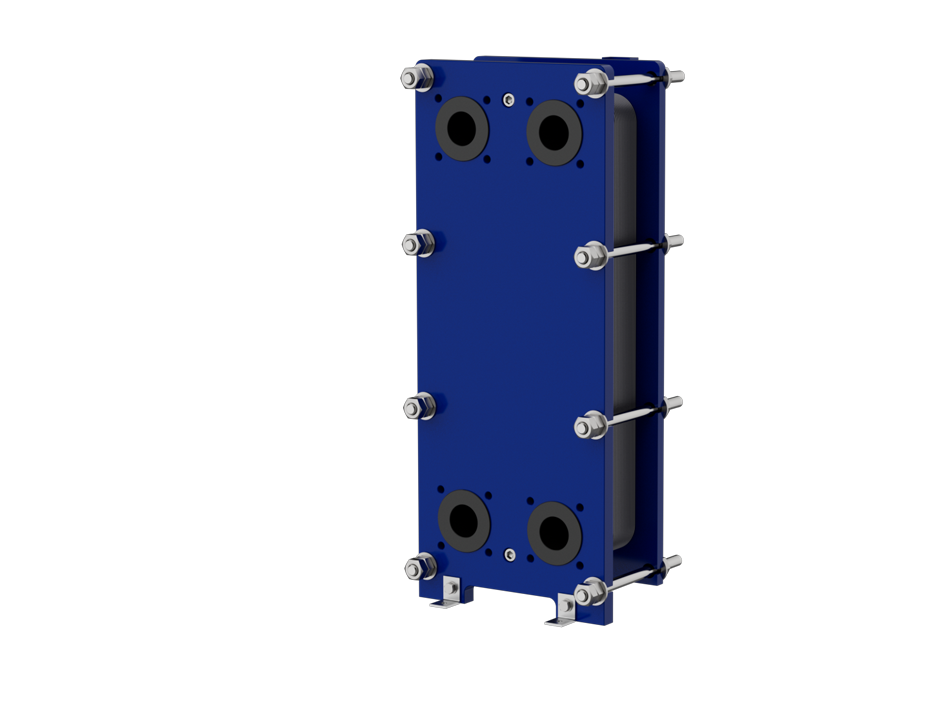

FREE FLOW PLATE HEAT EXCHANGERS

For fibres, particles and high viscous products

ZILONIS Energy Solutions’s new Free Flow plate heat exchanger series is ideally suited for difficult media containing solids, particles, fibres, and high viscous products. The Free Flow plates corrugation is designed for special tasks, where the conventional plate heat exchanger usually has a higher risk of fouling or clogging.

For the Free Flow plate series, the key focus lies in reliability and high performance. If the plate heat exchanger is not suited for the operating media, the intervals between maintenance and the risk of fouling are increased.

Features

Every detail is carefully designed to ensure optimal performance, reduced maintenance costs and decreased downtime:

- Compact design

- Lock gasket system

- Gentle product handling

- Suitable for products with solid particles

- Design pressure up to 10 bar

- Operating temperature: up to 180 °C

- Fixed bolt head

- Lifting lug

- Lining

- Lock washer

Applications

Accessories

Benefits

- Dairy/food/beverage industry

- Sugar industry

- Biogas industry

- Wastewater industry

- Pulp and paper industry

- Mining industry

- Drip tray

- Insulation jackets

- Safety cover

- Assembling spanner

- Foundation feet

- Designed for CIP cleaning

- Easy assembly

- Cost-affective

- Designed to combat fouling

- Clog resistant

- The inlet area is designed for optimal distribution and flow across the plate

- No dead spots on the plate

Plates

High and low

The wide channels provide enough room for difficult media to flow freely. The pattern of horizontal waves maintains no plate contact points in the flow direction, ensuring gentle treatment of the output product.

The clearance between the heat transfer plates measures up to 12 mm gab depending on the plate type.

The ZILONIS Energy Solutions SFF151 and SFF301 Free Flow Plate Heat Exchanger is specially designed to mix both viscosity and flow. The design consists of two different plate patterns: “ZILONIS Energy Solutions HIGH” and “ZILONIS Energy Solutions LOW”, which can be assembled for either 12/6 mm or 9/9 mm plate gab.

Designed to meet your needs – Our extensive range ensures that we can offer the best solution at the best price and, if required, combine several different types of heat exchangers to ensure that you get the best possible solution.

Gaskets:

• Click on gasket – a glue less system for sealing

• Materials: NBR, EPDM and Viton

• Other materials available on request

Frame:

• Painted frame, RAL 5010 (available in other colours)

Construction standards:

• EN13445

• ASME sec VIII, Div. 1

Design pressure:

• Painted frames: 1.0 MPa (145PSI)

• Stainless steel frame: 1.0 MPa (145 PSI)

• Max. differential pressure 156 bar

Plate material:

• AISI 304/316 and titanium

• Other materials available on request

Plates – The wide channels provide enough room for difficult media to flow freely. The pattern of horizontal waves maintains no plate contact points in the flow direction, ensuring gentle treatment of the output product.

The clearance between the heat transfer plates measures up to 12 mm gab depending on the plate type.

High and Low – The ZILONIS Energy Solutions SFF151 and SFF301 Free Flow Plate Heat Exchanger is specially designed to mix both viscosity and flow. The design consists of two different plate patterns: “ZILONIS Energy Solutions HIGH” and “ZILONIS Energy Solutions LOW”, which can be assembled for either 12/6 mm or 9/9 mm plate gab.

Products

SFF50 Series

The SFF50 series has an inlet and outlet socket diameter of 56mm.SFF100 Series

The SFF100 series has an inlet and outlet socket diameter of 96mm.SFF150 Series

The SFF150 series has an inlet and outlet socket diameter of 145mm.SFF200 Series

The SFF200 series has an inlet and outlet socket diameter of 190mm.SFF300 Series

The SFF300 series has an inlet and outlet socket diameter of 290mm.INDUSTRIES

Food

Chemical And Petrochemical

Power Engineering

Building Services Engineering

Pharmaceutical

Wood and Paper

Oil and Gas

Marine

Newsletter

Product and technological news